Introduction

CALMS compressed air optimization platform, has taken a whole new approach to improve the reliability, financials and sustainability of compressed air systems. The 5-step approach systematically identifies potential savings and leads steps by step towards energy and sustainability excellence with improvements opportunity cards.

Each of the steps contains specific actions that will be automatically identified and suggested to create a more energy-efficient system and reduce carbon footprint. The system as a whole is analysed and monitored. The steps towards continuous improvements.

Based on identified opportunities for improvements CALMS will create cards under each step.

Each improvement opportunity card will contain current situation and opportunity description with link to action in CALMS and link to detail explanation and identified impact on :

- Reliability

- Financial

- Sustainability

Disclaimer: Final solution must be verified by CA expert.

Action cards list and description

Create system review

This is the first card when you add new system. Card will pop up under Assessment group. Until complete System review and system setup will be done System KPIs will not work.

Conduct a comprehensive system review to gain a thorough understanding of the compressed air system’s design, operation, and potential savings opportunities. This crucial first step provides the foundation for informed decision-making and targeted improvement actions to enhance overall efficiency and performance.

The minimum requirements for System Review are at least one note or opportunity, complete System details page with CA cost and TCO-Total Cost of Ownership and Setup, complete all answers on Efficiency and Reliability page and saved Potential savings.

Complete system review

System review is not completed, all pages must be filled completely before any new actions and analysis can be done.

Same as Create a system review card.

Decrease system pressure

Before decreasing system pressure measure pressure across the factory and check for the lowest pressure. Best is to start with monitoring or audit.

Too low pressure can cause even more damage to the production.

Too high pressure will cause energy inefficient system.

Our recommendation is to operate compressed air for standard instrument air at system pressure 6-6.5 bar (90-95PSI) or lower. If air system piping does not support this kind of pressure we would suggest to develop a generic piping schematic diagram for use in conducting a thorough system assessment.

Install pressure drop indicators

Purpose of differential pressure monitoring devices in connection with monitoring will bring numerous benefits to regularly changing compressed air filter elements like:

- High quality compressed air

- Protection of adsorption (desiccant) dryer beds

- Protection of downstream equipment, personnel and processes

- Reduced operational costs

- Increased productivity & profitability

- Continued peace of mind

Differential pressure is a measurement of pressure loss in a compressed air system. To achieve a constant downstream pressure required to operate equipment and processes, an air compressor must often operate at a higher operating pressure and/or for longer periods to overcome the pressure losses.

Every 14.5 psi (1 bar) of differential pressure an air compressor (positive displacement type) must overcome is equal to approximately 7% increase in electrical consumption. So, while keeping differential pressure losses low is good practice, compressed air quality is the main reason for changing a filter element.

Cost of maintenance and replacement parts are insignificant compared to those associated with product spoilage should a filter element fail. What seems like a cost savings in the short term can turn out to be a costly mistake. Therefore, filter elements should primarily be replaced based upon manufactures recommendations to maintain air quality.

Secondary consideration should also be given to system pressure losses; however, for almost all modern compressed air systems, this should not be the main reason to change filter elements. The exception to this may be more applicable to older, more heavily contaminated compressed air systems, when it may be more cost effective to change filter elements before the manufacturers recommendation as the cost of replacement elements will be significantly lower than the energy cost associated with operating with higher differential pressures.

Install heat recovery

Compressing air gives heat and as much as 90% of that heat can be recovered for use in your operation. Your compressed air system represents an excellent source for heat recovery and could improve the efficiency of the system overall. Improving the performance of your compressed-air system reduces your plant wide energy costs.

Consult energy manager and expert to identify heat recovery opportunity. For estimation you can use heat recovery calculator.

If you can supplement or replace the electricity, gas or oil needed to create hot water for washrooms, or direct warm air into a workspace, warehouse, loading dock, or entryway, the savings can really add up. The possibilities to recover this waste heat via hot air or hot water are good. The return on the investment for energy recovery is usually as short as one to three years. In addition, energy recovered by means of a closed loop cooling system (for water cooled compressors) is advantageous to the compressor’s operating conditions, reliability and service life due to an equal temperature level and high cooling water quality to name but a few.

Change dryer type

Adsorption dryers are consuming lot of energy or air for regeneration and in some factories low dew point is not necessary for all consumers so dryers can be replaced with refrigeration dryers or more efficient HOC dryers.

With the help of expert calculate saving potential for replacing those dryers.

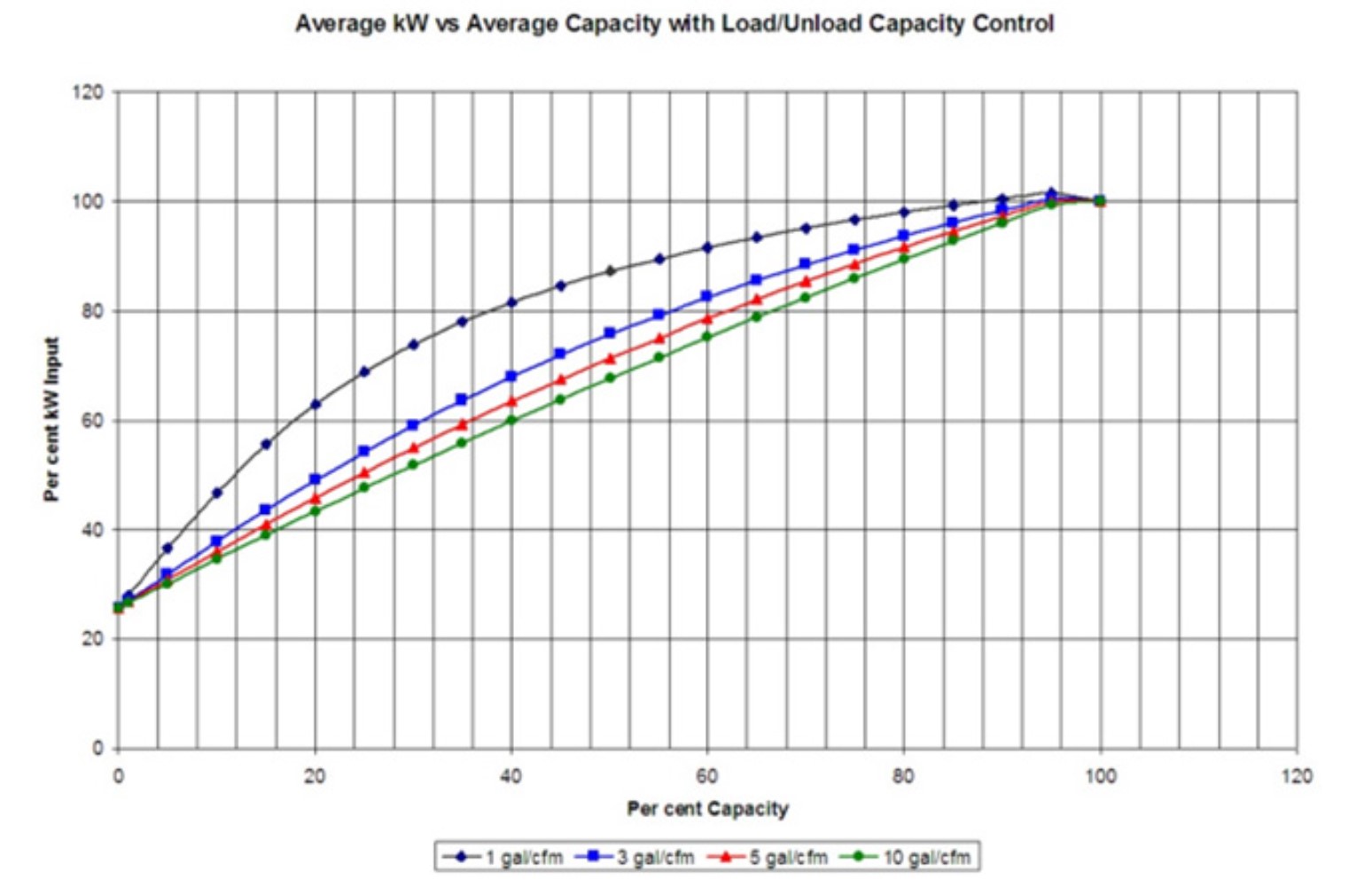

Increase system capacitance

Installed receivers and volume of main pipes are too small for your flow profile demand, causing pressure fluctuation and frequent loading of compressors. For an efficient operation of a compressed air system the size of the compressed air receiver is critical.

Capacitance (m3/bar) is defined as the amount of air needed (over what is already being supplied) to raise (or lower) the system pressure by 1 bar.

Adding bigger size of receivers/tanks is often better for system operation but also space and cost must be considered (law of diminishing returns)

Based on monitoring flow profile correct tank sizing would not be a problem.

We recommend that the receiver should be sized to protect the largest system event. You can use control storage calculator.

The minimum amount of storage recommended is 1 gallon per 1 cfm of capacity or 160 litre per 1 m3/min. This should be increased to 4 to 10 gallons per cfm or 640 litre to 1600 litre per m3/min of capacity for systems with sharp changes in demand.

Typical flow vs. power curves at various receiver sizes for load/unload lubricated compressors.

In industrial applications where air pressure is subject to large fluctuations or variations, air receivers are beneficial. In these situations, the increased compressed air requirement is compensated by air from local air receivers thus minimising idling at the generation station. The receivers subsequently replenish slowly using control valves to minimise peak energy demand on the compressor station. In addition to reduced compressor cycling, air receivers provide protection for end users that require high pressure by minimising the system pressure drop off while supporting the speed of transmission response in supply.

Install Flow controller

A Pressure/Flow Controller installed downstream of the properly-sized air storage receiver(s) and upstream of the main piping header leaving the compressor room is designed for this task. It senses the pressure at its outlet and modulates the flow control valve(s) accordingly to control the air flow from the receiver to hold the pressure constant. If more air is flowing away than in, the air expands and pressure decreases. The Pressure/Flow Controller opens sufficiently to release air from storage to bring pressure back to the set point. Conversely, if more air is flowing in than out, pressure is increasing and the Pressure/Flow Controller closes to hold air back in the receiver to correct the offset. The Pressure/Flow Controller isolates the supply side from the demand side dynamics and typically stabilizes the delivered air pressure +/- 0.07 bar (1psi) or less.

Stabilizing the pressure in the main distribution header eliminates the need to compensate for the fluctuating air pressure by raising the overall system pressure. The delivered air pressure from the Pressure/Flow Controller is set to more closely approach the minimum acceptable. Leaks and unregulated demands in the system consume less air when supplied at the lower pressure.

Significant reserve energy is available from air compressor motors that are running but not fully loaded. In combination with the Pressure/Flow Controller and air storage receiver, this reserve energy can be applied in a proactive manner to maintain an optimal balance point. As the receiver pressure changes, the trim compressor loads and unloads accordingly. For systems equipped with a network control system, instrumentation of the change allows a signal to be sent to automatically sequence the operation of the compressors in the network.

Running a partially loaded fixed speed compressor is inefficient and can be costly. Storage, therefore, is typically sized to allow unneeded compressors to time out and shut down. Ideally, all operating compressors run at full load with only one compressor trimming at any given time. Substantial air storage must be applied to cover any peaks so a shut down compressor doesn’t have to restart.

The advances in variable speed drive compressors (VSD) offer even greater opportunities to save energy and further enhance the overall performance of a system. Unlike a fixed speed compressor, there is no penalty for operating a VSD compressor partially loaded. Horsepower balances with the demand over the full capacity range of the compressor. A VSD compressor can be oversized to provide additional reserve energy without introducing an added operating cost burden.

The application of a Pressure/Flow Controller with the VSD compressor(s) offers additional savings opportunities and greater stability. Without supplemental storage, a VSD compressor tends to become reactive and ends up constantly chasing the dynamic demands, stressing the compressor motor. The Pressure/Flow Controller eliminates the oscillation and allows the VSD to operate at its maximum efficiency. Additional savings of 7-10% can be realized.

Main pipeline size redesign - high air speed in distribution line

The piping system design is crucial to operating the compressors at lower pressures. Piping configuration frictional line losses can be significant. Short-duration, high ‘surge-flow’ conditions also can affect system pressure.

Our recommendation is to operate compressed air at system pressure 6-6.5 bar (90-95PSI) or lower. If air system piping does not support this kind of pressure we would suggest to develop a generic piping schematic diagram for use in conducting a thorough system assessment.

Main ring is generally the most efficient type of distribution layout. Air mains are usually sized on velocity and a velocity level of 6 to 9 m/s (20-30 fps) is common as this is sufficiently low to prevent excessive pressure drop and should also allow reasonable water separation. The local feeding mains can flow up to around 15 m/s (50 fps). However, in order to prevent adverse pressure drops, the flow velocity in the main header sections should not exceed circa. 6 m/s (20 fps).

It is best to replace any tee connections for directional angle entry connections or swept tees. Turbulence caused by a 90o tee connection can cause pressure drops resulting in back pressure sending a false “unload signal” to the compressors which can potentially cause excessive cycling of the compressor.

Incorrect pipe sizing and restrictions are a major source of pressure losses in the system. Losses in the interconnecting distribution pipework between the compressor and the header distribution piping are commonplace however, the losses along these lines should be kept to a minimum.

Repairing air leaks and installing additional compressors and expensive controls will not rectify a basic pipe distribution system or process machine operational issue. Having too many compressors in service, needing equipment maintenance work, upgrading controls and repairing large leaks certainly are issues that need to be addressed. However, do not allow improperly sized air piping and fittings at one or two process machines in your plant to dictate a higher pressure for the entire system.

Reduce air leaks - compressed air leak management

The key to the leakage challenge lies in finding better insights and using them to support decision-making. This way, companies can find and prioritise their most effective options, and balance objectives optimally. They can reduce the number of leaks, and predict and locate those that do still occur faster and more efficiently in case of using smart leak management and zone based monitoring, supported by CALMS under Waste.

To manage leakage really effectively, companies need to optimise five linked issues:

- Where on the network is leakage likely to occur?

- When a leak does occur, how can I narrow the search area to find it as quickly as possible?

- What is the optimal way to organise the work of fixing a leak?

- How can I optimise the pressure on the network so I don’t cause leaks?

- How can I allocate capital expenditure so that I replace vulnerable infrastructure before leaks occur?

Leaks in compressed air systems are a regular feature. The energy requirements served by compressed air systems are intermittent in nature, however leaks are constant and surprisingly, potentially significant. The monetary cost of leaks can be quite startling and perhaps a little eye watering.

For instance, one 4mm hole in a compressed air distribution pipe can cost €2,000 per annum on a typical compressed air system operating throughout the year and at 8 bar.

In addition to the monetary cost, leaks can cause significant pressure drops resulting in excessive compressor cycling. In an attempt to reduce the pressure loss in a system where excessive leakage is an issue, operators occasionally increase the system discharge pressure. However, this has the effect of exacerbating the problem by increasing the leakage rate and create more leaks in the future.

It is not uncommon for leakage rates to be around 20 – 30%. Leaks can occur at any point in the system with joints, drains, valves regulators etc being the most common sources. Fixing leaks in the most basic form can occasionally be as simple as tightening connections or applying a sealant at a strategic point. However, leaks will be found which require replacement of faulty components. It is worth noting that one of the most effective means of reducing leakage is to reduce the distribution pressure. Note, a 10% reduction in leakage would often be achieved through carrying out an appropriate leak reduction programme.

Log equipment maintenance

Implementing a systematic approach to logging equipment maintenance in compressed air systems is essential for optimal performance. This improvement action focuses on enhancing reliability, efficiency, and safety, leading to reduced energy consumption, minimized downtime, and lower maintenance costs. By proactively identifying potential issues and scheduling regular maintenance tasks, organizations can prolong equipment lifespan, ensure consistent air quality, and promote a safer working environment, all while contributing to environmental sustainability and competitiveness in the market.

A maintenance log for compressed air systems should include the following key elements:

- Equipment identification: Make, model, serial number, and location.

- Maintenance tasks: Type of maintenance performed, such as inspections, adjustments, cleaning, or repairs.

- Maintenance frequency: Scheduled intervals for each maintenance task.

- Date of service: When the maintenance was performed.

- Service personnel: Name or initials of the person who carried out the maintenance.

- Observations: Any issues detected or resolved, and any recommendations for future actions.

- Spare parts used: List of replacement parts or consumables used during maintenance.

- Hours of operation: Runtime hours of equipment at the time of maintenance, if applicable.

Increase system redundancy - back-up compressor

Based on system review there is no adequate back-up compressor available in case of failure or service of the biggest compressor.

Our suggestion would be to have N+1 redundancy available.

N+1 redundancy is a form of resilience that ensures system availability in the event of component-compressor failure. Components (N) have at least one independent backup component (+1). The level of resilience is referred to as active/passive or standby as backup components do not actively participate within the system during normal operation.

Redundancy is a system design in which a biggest compressor is duplicated so if it fails there will be a backup. Redundancy has a negative connotation when the duplication is unnecessary or is simply the result of poor planning.

System redundancy = (Total system capacity - System flow capacity) / Biggest compressor capacity * 100%

In system review estimation we are using power instead of capacity

System redundancy:

- < 100% - unreliable system without enough backup

- 100% - system has backup capacity for biggest compressor

- 100 - 200% - well designed and reliable system

- 200% - system with overcapacity

Decrease system specific power

Decrease pressure drop across air treatment

Reducing pressure drop across compressed air treatment equipment, such as dryers and filters, improves overall system efficiency, lowers energy consumption, and minimizes operating costs. This improvement action focuses on optimizing treatment components for better performance and reduced energy waste, ensuring high-quality compressed air supply for various applications.

Achieving a reduced pressure drop across compressed air treatment equipment can be accomplished through several steps:

- Proper selection: Choose the appropriate dryers and filters for your specific application, considering capacity, pressure rating, and air quality requirements.

- Regular maintenance: Clean or replace filter elements and dryer desiccant regularly, as per the manufacturer’s recommendations, to ensure optimal performance and prevent pressure drop increase over time.

- Correct sizing: Ensure that dryers and filters are sized correctly for the required flow rate, as undersized equipment can cause excessive pressure drops.

- Optimize layout: Minimize the length of piping and the number of bends, elbows, and other fittings between the compressor and treatment equipment to reduce pressure losses.

- Monitor pressure: Regularly check pressure gauges before and after the treatment equipment to identify any significant pressure drops, which may indicate a need for maintenance or replacement.

- Upgrade equipment: Consider upgrading to high-efficiency dryers and filters with lower pressure drop designs, such as those utilizing larger filter media or innovative flow paths.

- Reduce system pressure: Lowering the overall system pressure can help decrease pressure drop across treatment equipment, as long as the reduced pressure still meets the requirements of your applications.

- Bypass installation: For systems with varying air quality requirements, install bypass lines around dryers or filters that are only needed for specific applications. This allows air to bypass the treatment equipment when high-quality air is not required, reducing pressure drop in the system.

By following these steps, you can effectively decrease pressure drop across compressed air treatment equipment, enhancing system efficiency and reducing energy consumption.

Improve condensate management

Improving condensate management in compressed air systems is essential for maintaining air quality, prolonging equipment lifespan, and enhancing system efficiency. This improvement action focuses on optimizing condensate drainage, separation, and disposal, reducing the risk of contamination and corrosion while minimizing energy waste and environmental impact.

Under average conditions, every 100 cfm of air compressed to 100 psig (6.89 barg) produces approximately 20 gallons (75.7 litres) of condensate per day which needs to be treated.

Use CALMS “Condensate load” calculator to calculate the amount of water in compressed air.

Improving condensate management in compressed air systems can be achieved through the following steps:

- Proper drainage: Ensure that all components of the compressed air system have adequate drainage points, such as automatic or manual drains, to remove condensate efficiently and prevent accumulation.

- Correct installation: Install piping with a slight slope towards the drainage points to facilitate proper condensate flow and prevent pooling or backflow.

- Timed or zero-loss drains: Use automatic timed drains or zero-loss drains that only discharge when condensate is present, minimizing air loss and energy waste.

- Regular maintenance: Check and clean condensate drains regularly to prevent blockages and ensure optimal performance.

- Condensate separators: Install high-quality condensate separators to remove contaminants, such as oil and particulates, before discharging the condensate into the drainage system. This helps to protect the environment and comply with local regulations.

- Dryer selection: Choose the appropriate air dryer type, such as refrigerated, desiccant, or membrane dryers, based on your specific application and air quality requirements. Properly functioning dryers reduce condensate formation and improve overall air quality.

- Monitor and inspect: Regularly inspect condensate management components for signs of wear, corrosion, or leaks. Monitor condensate discharge to ensure proper functioning and compliance with environmental regulations.

- Training: Educate personnel on the importance of condensate management and proper maintenance procedures to ensure consistent implementation across the facility.

By implementing these measures, you can effectively improve condensate management in compressed air systems, leading to enhanced air quality, reduced energy consumption, and minimized environmental impact.

Decrease excessive distribution pressure

Decreasing excessive distribution pressure in compressed air systems is a vital improvement action for enhancing energy efficiency, reducing operating costs, and prolonging equipment life. This approach involves optimizing system pressure settings, identifying and addressing pressure drop sources, and implementing proper maintenance practices to ensure consistent air pressure and quality throughout the facility.

Our recommendation is to operate compressed air at system pressure 6-6.5 bar (90-95PSI) or lower. If air system piping does not support this kind of pressure we would suggest to develop a generic piping schematic diagram for use in conducting a thorough system assessment.

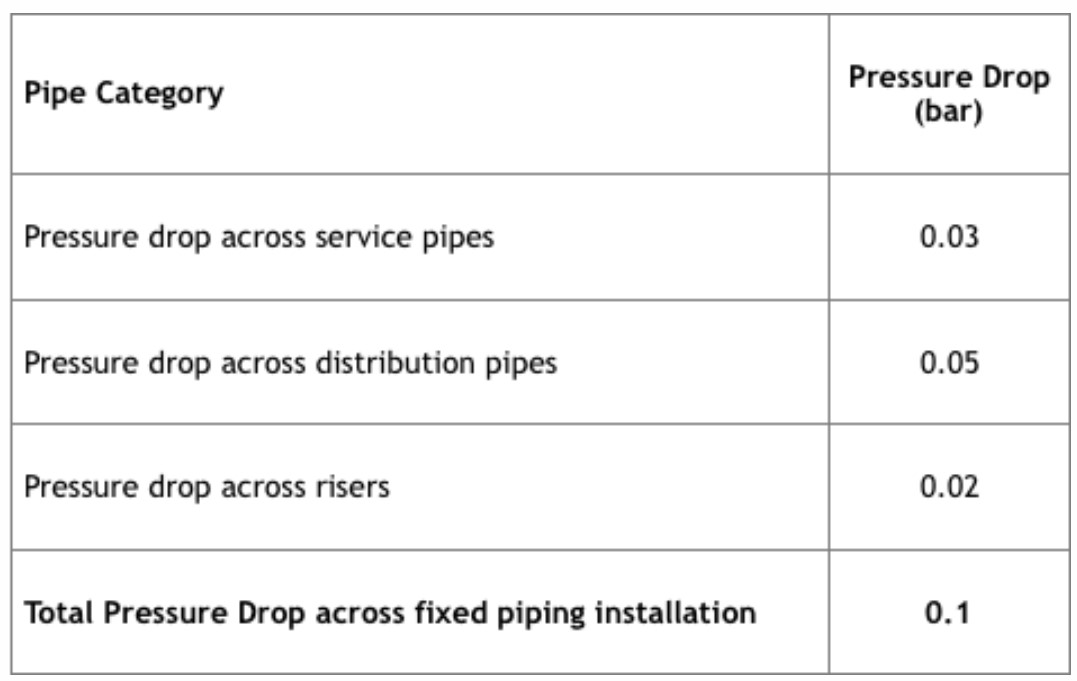

Main pipeline size redesign - high pressure drop in distribution piping

In general, fixed compressed air distribution systems should be sized such that the pressure drop in the pipes does not exceed 0.1 bar (1.45 psi) between the compressor room and most remote demand point. The pressure drop arising from flexible hoses, couplings and fittings should also be included in the pressure drop calculation. However, if possible, in an attempt to reduce pressure losses, the number of bends, valves, fittings or flow obstructions should be kept to a minimum.

An ideal distribution system provides a sufficient supply of compressed air to all demand points at the required pressure. Inadequate or poorly designed compressed air distribution systems can lead to low productivity, poor equipment performance and high energy bills. When designing a compressed air system, it is therefore good practice to consider the factors which help improve the efficiency and reliability of the compressors and ancillary equipment, minimise leakage and pressure drops and improve compressor life-cycle cost.

A useful approach is to design a ring main or looped piping system to serve the space where the compressed air consumption will take place. This is an effective way to minimise pressure drop in a system. Branch pipe connections are then run from the loop to serve the various demand points. This helps provide for a uniform compressed air supply as the air distributed to the demand point from two directions.

The design of a ring main system is a recommended approach however, may not be entirely suitable in scenarios where there are large compressed air consumers located at a much greater distance from the compressor installation. It is recommended that a separate compressed air main should be routed under these circumstances to serve this equipment.

Inadequate documentation - collect and update project documentation and PI&D

Addressing inadequate documentation in compressed air systems is an essential improvement action that involves collecting and updating project documentation and Piping and Instrumentation Diagrams (P&IDs). This approach ensures accurate system representation, facilitates effective maintenance and troubleshooting, and supports informed decision-making for system optimization and upgrades.

Start with System Setup Equipment PI&D diagram and fill in all equipment data sheets.

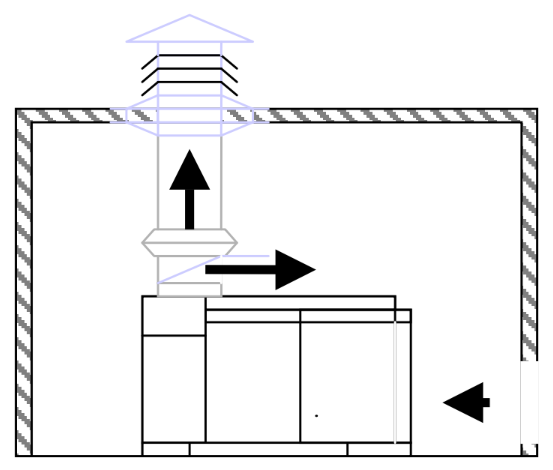

Possible high temperature in the compressor room

Addressing high temperatures in the compressor room is a crucial improvement action that involves optimizing ventilation, cooling systems, and room layout. This approach enhances the performance and efficiency of compressed air equipment, extends the lifespan of components, and maintains a safe working environment for personnel.

Decreasing the ambient temperature in the compressor room can lead to improved efficiency in the compressed air system.

For every 3°C (5.4°F) reduction in intake air temperature, the compressor efficiency can improve by approximately 1%.

However, actual efficiency gains may vary depending on the specific equipment, compressor type, room layout, and other factors. It’s essential to evaluate your unique system to determine the actual efficiency improvement achievable.

In the case of industrial compressors, the cooling air should always be removed by forced ventilation (fans) and ducting.

Improve cooling air quality

Improving cooling air quality in compressed air systems is a vital improvement action that involves optimizing intake air filtration, maintaining a clean environment, and ensuring proper ventilation. This approach enhances compressor performance and efficiency, reduces wear and tear on components, and prolongs equipment life, ultimately leading to lower operating costs and improved system reliability.

Increase or clean space around equipment for service accessibility

Increasing or cleaning space around compressed air equipment for service accessibility is an essential improvement action that involves optimizing room layout, decluttering, and maintaining a clean working environment. This approach enhances maintenance efficiency, ensures the proper functioning of equipment, and promotes a safer workspace, leading to improved system performance and reliability.

It is recommended that at least 1 meter (3 ft) of space be around the compressor.

The compressor must be installed to allow ease of access for operation and servicing. For cooling to be assured there must be a certain minimum distance between the ventilation fan or cooler and the neighboring wall or other components within the compressor system. If this is not the case the cooling is reduced. When there are multiple compressors installed the cooling air discharge of one compressor must not be used as the cooling air for another. Nor should the cooling air of the compressor be used for the cooling air of the air dryer.

Improve daily equipment checklist

Improving the daily equipment checklist for compressed air systems is a crucial improvement action that involves refining inspection protocols, updating maintenance guidelines, and ensuring proper staff training. This approach enhances system reliability and efficiency, promotes early detection of issues, and supports effective preventive maintenance, ultimately resulting in reduced downtime and lower operating costs.

A daily compressed air equipment checklist should include the following items:

- Visual inspection: Check for leaks, loose connections, corrosion, or signs of wear on equipment and piping.

- Air filter condition: Inspect and clean or replace air filters as needed to maintain optimal airflow and air quality.

- Lubrication: Verify proper lubrication levels for compressors and other equipment requiring lubrication, and top off or change oil as needed.

- Compressor operation: Monitor compressor pressure, temperature, and operating hours to ensure proper functioning.

- Drain functionality: Check condensate drains for proper operation, and clear any blockages or debris.

- Cooling system: Inspect and clean cooling fans, heat exchangers, and other cooling system components to maintain optimal temperature control.

- System pressure: Monitor system pressure for any fluctuations or excessive pressure drops that could indicate potential issues.

- Unusual noises or vibrations: Listen for any abnormal sounds or vibrations from the equipment that might indicate mechanical problems.

- Safety devices: Test safety valves, pressure relief devices, and other safety equipment to ensure proper operation.

- Maintenance log: Record all inspections, maintenance tasks, and observations in a maintenance log for future reference and analysis.

Note that the specific items on the checklist may vary depending on the type and complexity of the compressed air system in use.

Design and add a spare connection for rental equipment in an emergency situation

Designing and adding a spare connection for rental equipment in compressed air systems is a proactive improvement action that ensures rapid integration of backup equipment during emergency situations. This approach enhances system resilience, minimizes downtime, and helps maintain continuous production, ultimately safeguarding both operational efficiency and revenue.

Consider doing a yearly audit

Considering a yearly independent audit for compressed air systems is a valuable improvement action that accounts for the fact that these systems are live and continuously changing. Regular evaluations of system performance, efficiency, and maintenance practices help identify potential issues, energy-saving opportunities, and areas for optimization. This approach ultimately enhances overall system reliability, reduces operating costs, and ensures compliance with industry standards and best practices, while adapting to the dynamic nature of compressed air systems.

Consider purchasing new equipment - compressors to replace old ones

Considering the purchase of new compressors to replace old ones in compressed air systems is a strategic improvement action that enhances system efficiency, reliability, and sustainability. Upgrading to modern, energy-efficient equipment not only reduces energy consumption and operating costs but also minimizes downtime and maintenance expenses, ultimately providing a more cost-effective and environmentally friendly solution for the long term.

Consider using a service contractor for compressors that performs preventive maintenance to keep possible downtime to a minimum

Considering the use of a service contractor for compressor preventive maintenance is a proactive improvement action with numerous benefits. By entrusting experienced professionals with regular maintenance tasks, organizations can:

- Efficiently address potential issues, extending equipment lifespan and maintaining a reliable compressed air system.

- Reduce operating costs and enhance productivity by minimizing downtime and disruptions.

- Access specialized expertise and up-to-date knowledge of industry best practices, ensuring optimal equipment performance.

- Free up internal resources, allowing staff to focus on core business activities and other critical tasks.

- Enhance safety and compliance with regulatory standards, as service contractors are knowledgeable about relevant regulations and procedures.

- Benefit from objective assessments and recommendations, providing valuable insights for further system optimization and improvements.

- Improve budgeting and cost control, as service contracts often offer predictable maintenance expenses and can help prevent unexpected repair costs.

By engaging a service contractor for compressor preventive maintenance, organizations can enjoy these benefits and more, ultimately contributing to a more efficient and cost-effective compressed air system.

Consider overhauling or replacing old compressors

Considering overhauling or replacing old compressors in compressed air systems is a vital improvement action that aims to enhance system efficiency, reliability, and overall performance. By refurbishing or upgrading to newer, energy-efficient equipment, organizations can reduce energy consumption, decrease maintenance expenses, minimize downtime, and extend the lifespan of the system, ultimately resulting in a more cost-effective and environmentally friendly solution.

Inadequate redundancy of compressors

Addressing inadequate redundancy of compressors is an essential improvement action that ensures continuous operation and minimizes downtime in compressed air systems. System redundancy, or Available Redundant Capacity, is a term used in capacity planning to determine if a facility can safely add new compressed air users or lines without overloading the system or requiring the purchase of a new compressor.

Redundancy is a system design where the largest compressor is duplicated, providing backup in case of failure. However, redundancy can be seen as negative when it results from poor planning or is unnecessary.

Check CALMS System redundancy

Install a bypass across filters and dryers

Installing a bypass across filters and dryers is a practical improvement action for compressed air systems that enhances flexibility and minimizes downtime during maintenance or equipment failure. By implementing bypass lines, organizations can maintain a continuous air supply, even when filters or dryers require service, ensuring uninterrupted operation and improved system reliability.

Order new equipment maintenance

Equipment regular service is very important for reliable and efficient compressed air system operation.

Scheduling and ordering new equipment maintenance when service is overdue is a crucial improvement action for compressed air systems. Timely maintenance ensures optimal equipment performance, prevents potential issues, and extends the lifespan of the system. By proactively addressing overdue service, organizations can enhance system reliability, efficiency, and safety, ultimately reducing downtime and operating costs.

Perform an external audit

Performing an external audit, especially if one has not been conducted in a long time, is an essential improvement action for compressed air systems. By engaging an independent expert to evaluate system performance, efficiency, and maintenance practices, organizations can obtain unbiased insights and recommendations for optimization. An external audit offers a fresh perspective, helping to identify potential issues and opportunities for improvement, ultimately enhancing system reliability and reducing operating costs.

Start using smart monitoring

Implementing smart monitoring in compressed air systems is a cutting-edge improvement action that facilitates ongoing optimization and supports ISO 50001 energy management initiatives. By adopting permanent monitoring solutions, organizations can continuously track system performance, efficiency, and maintenance practices, enabling real-time decision-making and adjustments.

Smart monitoring systems often provide automated analysis and suggest improvement actions based on trends and Key Performance Indicators (KPIs). This advanced technology helps identify potential issues and energy-saving opportunities, ensuring the compressed air system remains aligned with energy management goals and industry best practices.

By leveraging smart monitoring, organizations can achieve enhanced system reliability, reduced operating costs, and improved sustainability, all while maintaining compliance with energy management standards like ISO 50001.

Organize training for your employees to engage

Ongoing employee training helps cultivate talent from within your business. By retraining employees on current skills, you can increase productivity by preventing small, basic mistakes.

Organizing training for employees in compressed air systems is a valuable improvement action that fosters employee engagement and promotes a culture of continuous improvement. By educating staff about the costs, waste, and savings opportunities associated with compressed air, they become more aware of its impact and are better equipped to identify and suggest potential enhancements in their workplace.

Training drives employee engagement, a vital factor in achieving Energy Star certification, by empowering staff with the knowledge to optimize compressed air systems for enhanced efficiency and sustainability.

Training not only helps employees understand the complexities and expenses associated with compressed air, but it also highlights the environmental implications of inefficient usage. As a result, staff members become more proactive in identifying areas for improvement, such as pressure reduction, leakage detection and repair, noise reduction, and proper equipment shutdown.

Direct results of employee training include:

- Over 40% of participants being able to reduce pressure on at least one application

- More than 80% of participants finding leakages, with over 30% being repaired

- Over 60% of participants acknowledging excessive noise as a problem, with leakage reduction also contributing to noise reduction

- Over 25% of participants reporting the inability to shut off air supply or machines, emphasizing the need for low-cost investments in safety equipment

Investing in employee training not only enhances compressed air system efficiency and reduces costs but also contributes to a safer and more environmentally friendly workplace.

Replace filters more regularly

Implementing a more frequent filter replacement schedule is an essential improvement action for compressed air systems. Regularly replacing filters ensures optimal air quality, reduces pressure drops, and maintains system efficiency. By adhering to a consistent filter replacement plan, organizations can prevent excessive wear and tear on equipment, ultimately extending system lifespan, reducing maintenance costs, and improving overall performance.

A general rule of thumb is that every 1 bar (14psi) reduction in pressure drop can lead to approximately 7% energy savings in the compressor’s power consumption.

The typical breakeven point for replacing a filter element is when the pressure drop across it increases by 0.3 bar. At this point, the energy costs associated with the increased pressure drop outweigh the cost of replacing the filter element. By monitoring and maintaining filter elements and replacing them when they reach this threshold, organizations can optimize compressed air system efficiency, minimize energy consumption, and reduce operating costs.

Check condensate drains regularly

Regularly checking condensate drains is a crucial improvement action for compressed air systems, as it ensures proper condensate management and prevents potential issues related to moisture accumulation and contamination. By maintaining the functionality and efficiency of condensate drains, organizations can avoid air quality degradation, reduce corrosion and rust formation, and prevent system breakdowns caused by excessive water in the system.

Typical condensate volume can vary depending on factors such as compressor capacity, operating conditions, and ambient air humidity.

Use CALMS calculator Condensate load.

As a general guideline, a compressor under average conditions, every 100 cfm (3 m3/min) of air compressed to 100 psig (7 barg) produces approximately 20 gallons (75 liters) of condensate per day which needs to be treated.

However, it is essential to note that this value can vary greatly depending on the specific system and environmental conditions. Regularly monitoring and managing condensate volume is vital to maintaining a reliable and efficient compressed air system.

Change desiccant

Implementing a regular desiccant replacement schedule is an important improvement action for maintaining the efficiency of desiccant air dryers in compressed air systems. Benefits of timely desiccant replacement include:

- Consistent air quality: Replacing desiccant ensures the air dryer can effectively remove moisture from the compressed air, maintaining the desired air quality and preventing potential issues related to moisture accumulation.

- Reduced pressure drop: As desiccant ages and dust, it may cause an increased pressure drop across the dryer, leading to higher energy consumption. Regular desiccant replacement minimizes pressure drop and optimizes system efficiency.

- Extended equipment lifespan: By maintaining the desiccant’s effectiveness, the overall system experiences less wear and tear due to moisture-related issues, prolonging the lifespan of both the dryer and the entire compressed air system.

The frequency of desiccant replacement depends on the specific dryer type, operating conditions, and manufacturer recommendations.

Generally, desiccant should be replaced every 3 to 5 years, but this can vary depending on factors such as operating hours, temperature, and moisture load.

Regularly monitoring desiccant performance with dew point and adhering to manufacturer guidelines for replacement can help ensure optimal compressed air system performance and longevity.

Conform to standards

Adhering to standards like ISO 9001 and ISO 50001 and others is a valuable improvement action for compressed air systems, as it demonstrates a commitment to quality management, energy efficiency, and environmental sustainability. Compliance with these standards can lead to numerous benefits, including:

- Improved reliability: Implementing a robust quality management system (ISO 9001) ensures that best practices are followed in the design, installation, and maintenance of compressed air systems, ultimately enhancing system reliability and reducing downtime.

- Enhanced efficiency: Compliance with ISO 50001, an energy management standard, promotes continuous improvement in energy performance and efficiency, helping organizations optimize their compressed air systems and minimize energy consumption.

- Positive reputation: Adherence to these standards showcases a company’s dedication to quality and sustainability, fostering trust and confidence among customers, partners, and stakeholders.

- Cost savings: By improving system reliability and efficiency, organizations can reduce operational and maintenance costs, contributing to better financial performance.

- Regulatory compliance: Conforming to international standards can help companies stay up-to-date with the latest regulations and industry best practices, ensuring compliance with local and global regulations.

By integrating ISO 9001 and ISO 50001 standards into their operations, organizations can drive improvements in the reliability and efficiency of their compressed air systems while demonstrating a commitment to quality and environmental responsibility.

Start new training for employees

Initiate regular employee training to maintain up-to-date knowledge and promote ongoing engagement, as a lack of recent training can hinder progress in compressed air system optimization and overall efficiency. Continuous learning ensures staff stays informed and actively involved in improvement efforts.

For more info check Employee training

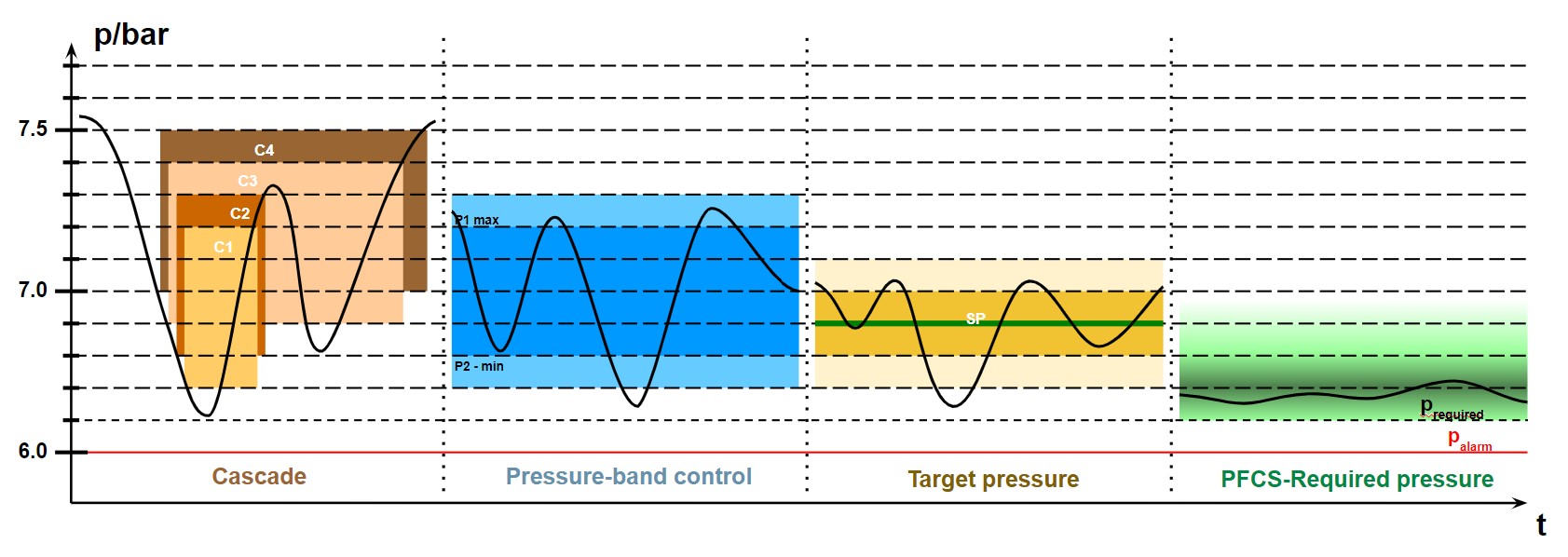

Install or set master control system

Implement a master control system to efficiently manage multiple compressors, optimizing energy usage and ensuring consistent pressure across the compressed air system, ultimately enhancing overall system performance and reducing operating costs.

The master controller allows to reduce the number of start-up cycles and compressor loads, which has a positive impact on the reduction of their mechanical wear and tear as well as the frequency and cost of maintenance and service.

Various control modes in comparison

IMPLEMENTATION

- The decision to install the master controller should be preceded by measurements of the operation of existing compressors with the expert and CALMS audit tools. The measurements allow to simulate the operation of the tested system to obtain information on how the system would work at a different air intake, with different compressors, with a different tank, at a lower pressure, and to estimate the time of return on investment and the selection of appropriate configuration of machines.

- Compressors do not have to be located in one room, but special load distribution must be taken into considiraton

Install or adjust variable speed compressor

Variable speed compressors or VSD compressor control can significantly reduce the energy wasted by compressors running in the unloaded condition.

VSD controls typically have four main pressure settings to control the start/stop or load/unload pressure bands that are used when the compressor runs below minimum speed and to set the VSD target, which is where the compressor will hold its discharge pressure while varying its speed. Normally parameters are controlled with PID loop.

Before starting with VSD integration or adjustment, perform a Compressed air System Audit!

VSD optimization

- Coordinate target setup and start/stop levels

- Decrease start/stop frequency by widening the pressure band

- Eliminate unloaded run time by reducing unload timer setting

- Install remote pressure sensing

- Adjust PID control settings

- Set timed scheduled pressure levels

- Eliminate minimum speed modulation

- Increase minimum inefficient speed settings

- Reduce maximum inefficient speed settings

- Pair VSD compressor with smaller compressor

It is common to see VSD compressors hold a very precise pressure at their discharge, while the plant pressure sags due to pressure differentials across piping, filters and air dryers. These pressure differentials may be small when flows are low, but large during plant peak demands. Since having a stable plant pressure is the ultimate goal, it is a good idea to make the pressure sensing of the compressor remote, where is can be done safely without exceeding the pressure capability of the compressor. Adding a remote pressure sensor allows the VSD to “see” past any pressure drops in the compressor room and precisely regulate plant pressure.

This measure also saves energy because the target pressure can be set exactly where it is needed rather than at an artificially high level to compensate for the worst case pressure differential. When flows are low, there is minimal pressure differential across clean-up components: Therefore, the compressor keeps its discharge low. During higher flows, the compressor will automatically increase its discharge pressure to compensate for the pressure differential, but only during these conditions.

Often, when a VSD compressor is installed that is too large for the load, the unit will spend most of its operating time in start/stop mode below the variable range. Most manufacturers will tell you that long-term operation in this mode is not desirable due to reasons already mentioned.

Optimizing certain end-use devices and remove inappropriate air applications

Many end use devices are energy inefficient. For instance in blowing and drying applications, ventilators can often be used with an energy savings benefit. In some applications, electrical or hydraulic equipment can cost effectively replace compressed air end use devices, and be more energy efficient. While equipment manufacturers’ catalogues usually state compressed air requirements for their machines, users do not always take this into account in their purchasing decisions.

The optimization of end use devices is one aspect of the system design issue.

While hand held pneumatic tools can be easily replaced by more efficient models, much CAS use results from devices (pistons, motors, etc.) which are components of large fixed machines, for which replacement or upgrading can be very costly.

Replacing pneumatic tools with electrical tools

Use calculator to calculate savings when replacing different pneumatic tools with electrical.

Many operations can be accomplished more economically using alternative energy sources. Inappropriate uses of compressed air include any application that can be done more effectively or efficiently by a method other than compressed air. Examples of potentially inappropriate uses of compressed air, along with suggested alternative solutions, include:

- Open blowing – brushes, brooms, blowers, nozzles, electric fans

- Sparging – low-pressure blowers and mixers

- Aspirating – low-pressure blowers

- Atomizing – low-pressure blowers

- Padding – low to medium pressure blowers

- Dense-phase transport – low to high pressure blowers

- Vacuum generation – dedicated vacuum pump or central vacuum pump

- Equipment or personnel cooling – fans

- Open blowing – brushes, brooms, blowers, electric fans, mixers, nozzles

- Vacuum venturis – dedicated vacuum pump or central vacuum system

- Plant clean up – low-pressure blowers, brooms, nozzles or electric fans

Reducing artificial demand due to overpressure and non-regulated use

Artificial demand or compressed air consumption is the excess volume of air that is created on unregulated users as a result of supplying higher line pressure than necessary for the applications. It includes leaks, drain valves, and blowoff…

As real production demand decreases and the pressure rises, artificial demand increases.

Companies can reduce the artificial demand by implementing an overall monitoring & controls system to maintain the compressed air system at the actual pressure that is required and by performing regular assessments.

During compressed air system and leak survey also end-use pressure regulators must be checked and set as per specification. Using PFC will reduce artificial demand in the majority of systems.

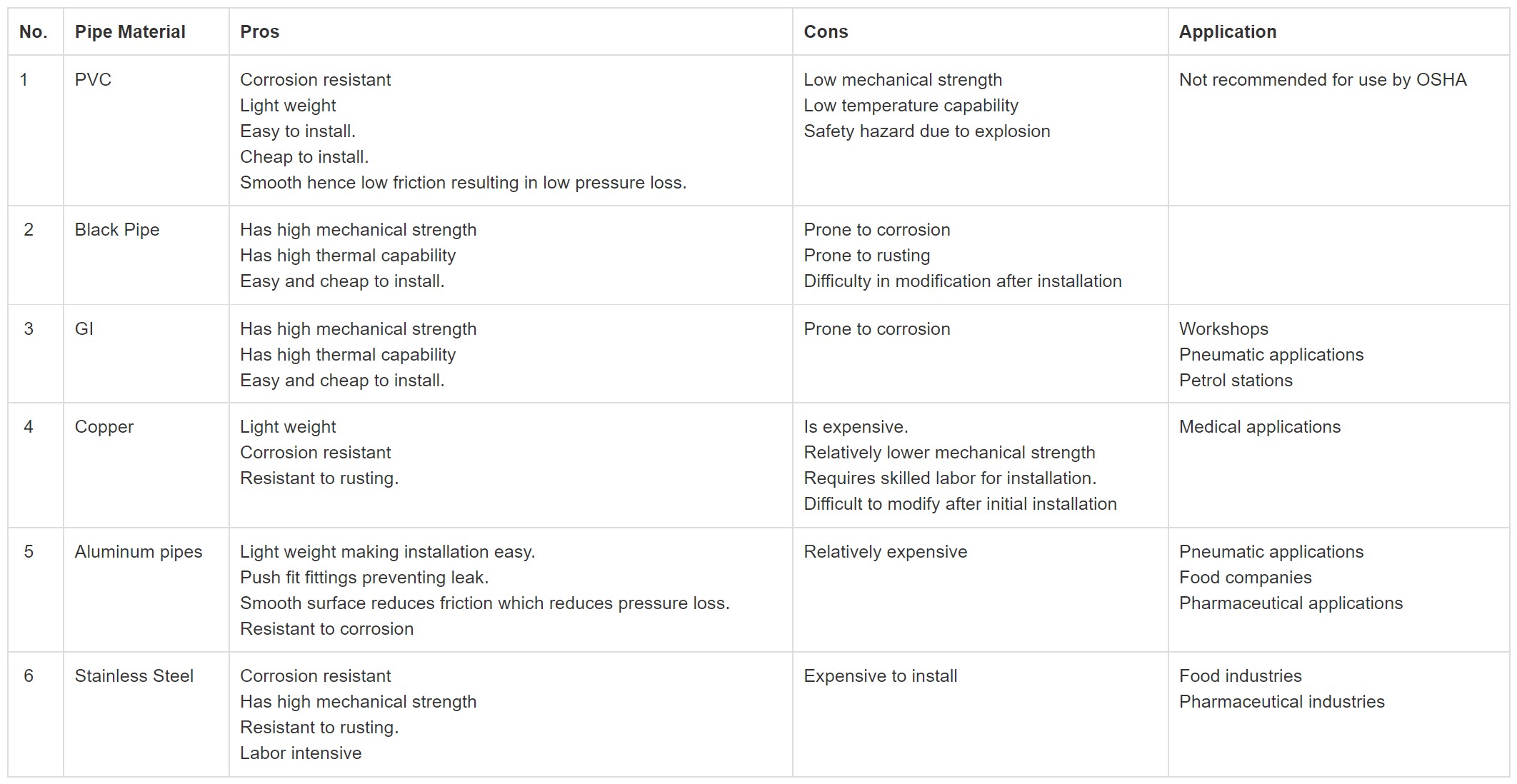

Replace or upgrade pipe type

Pipes used for transporting compressed air are available in a variety of materials such as – plastic, iron, stainless steel, copper, and aluminium among others. Compared to plastic, metal is the generally preferred installation material for its long-standing track record and a more common experience for technicians with its installation.

The major problems faced in a compressed air system include:

- Corrosion of metal pipes in acidic conditions

- Rust of metal pipes due to poor compressed air treatment

- Leaks at threaded joints.

- Safety hazards such as possible rupture of PVC pipes due to reactions with hydrocarbons from oil injected compressors at high temperature.

- Pressure loss due to improper pipe sizing and leaks along the piping system

To mitigate these problems, selecting the correct pipe material for your application is key.

Stainless Steel Pipe

This pipe is a good quality and reliable choice of compressed air since the pipes are strong and corrosion resistant. The stream of air produced from such pipes can be used in food and pharmaceutical industries. Installation of SS can be a labor intensive if welding or threading is involved, another option is using push fit SS pipes.

Aluminum Pipe

This is currently the compressed air piping of choice. These pipes are lightweight making installation works easier. Aluminum pipes are also resistant to corrosion and have a smooth inner surface. This ensures that the compressed air supplied to your machines is of high quality and the pressure loss within the system is minimal. The pipes are also relatively affordable as compared to Stainless Steel. If properly installed they can be leak free as well.

Copper Pipe

This pipe is an excellent choice for use in a compressed air system. Any condensate within the pipe will not result in corrosion. Copper pipes are also naturally antibacterial. They are the piping of choice for medical air and oxygen applications. These pipes are however expensive and require soldering by highly skilled personnel to produce good quality installation work.

Galvanized Iron pipe

These pipes are used for general plumbing and are less likely to corrode than black pipes. Over time the galvanized layer flakes off and the pipe inevitably rusts. The flakes and rust are carried by the compressed air to the user points. Those pipes are using threads and as such are prone to leaks.

The debris carried by the compressed air can damage pneumatic cylinders and even cause bodily harm when coming out of a blow gun. When using GI pipe, it is advisable to keep moisture out of the system using a dryer and to use the proper pipe class.

Black pipe

This iron pipe has been in use for decades. Most people prefer it since installation is easy, the fittings are readily available and cheap. Compressed air systems tend to have moisture and rust in black iron pipe is inevitable. The rust will then be carried on with the compressed air piping which will then damage pneumatic tools.

The other issue with black pipes are leaks if you are using joints with threads. Better option is using welded joints.

PVC pipe

When dealing with compressed air systems, the use of PVC pipes should be avoided at all costs! While PVC pipes are cheap, easy to install and flexible, these pipes pose a great danger not only to your compressed air system but to people working around as well.

PVC pipes experience degradation overtime when used for compressed air systems. The degradation makes the pipe brittle and easy to crack when under pressure. The shattering makes the pipe unsafe for use therefore, consider other options for compressed air piping.