8 – HMI OP OPERATOR PANEL OVERVIEW

PM-2 and PM-4 are using smaller 4,3’’ HMI, PM-8 is using bigger 7’’ HMI.

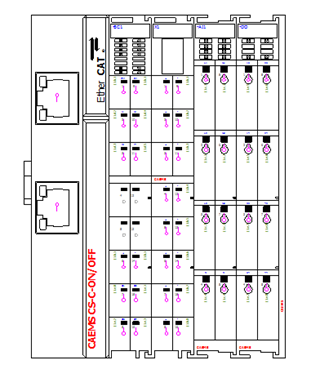

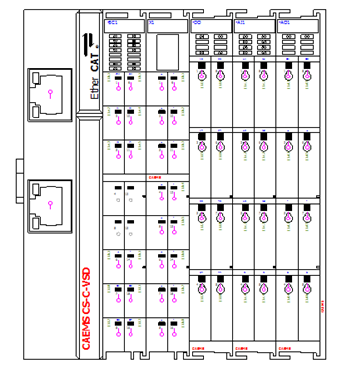

4,3’’ HUMAN MACHINE INTERFACE (FOR PM-2 AND PM-4)

STATUS SCREENS

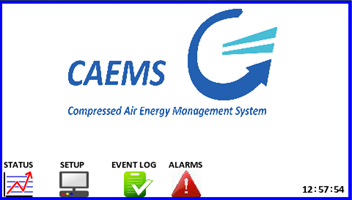

CAEMS can be ordered with an optional HMI operator panel. When powering

up the unit the operator panel (OP) will display the HOME screen.

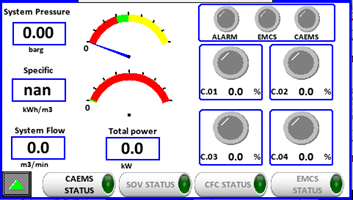

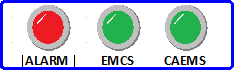

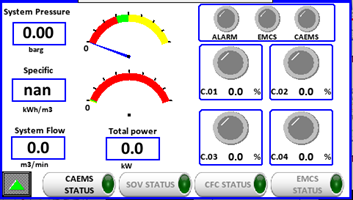

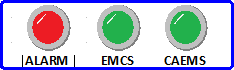

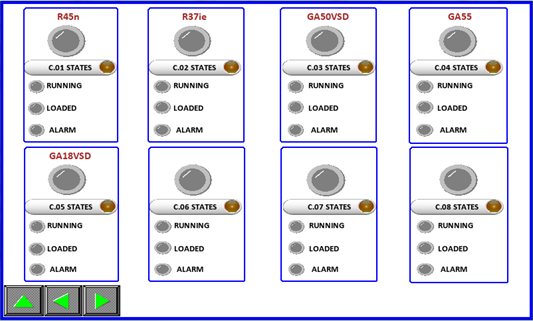

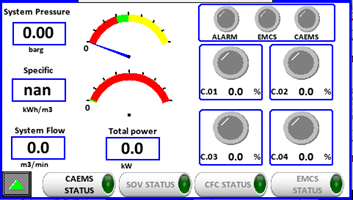

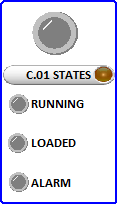

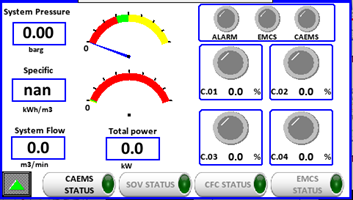

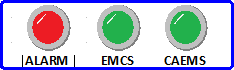

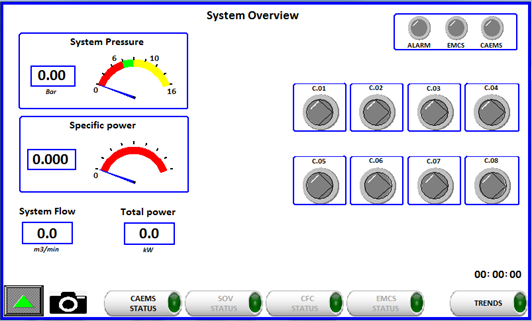

Pressing the icon will send you to the CAEMS status menu. Here you have

an overview of your sistem. The squares on the right represent ALARM,

EMCS, CAEMS and compressors status.

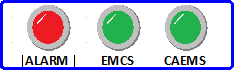

If any of the states in the upper right corner is active the signal

lights will lid up. Below is a picture to represent the status light

color. Alarm LED is ON when system alarm is active. Which alarm is

active you can check in Alarm status page.EMCS light is ON if EMCS

Control feature is enabled. CAEMS light is ON if CAEMS is activated in

general settings, pressure is beyond critical and at least one

compressor is running.

In the right corner below there are 4 status light to indicate single

compressor state. Compressor states are:

In the right corner below there are 4 status light to indicate single

compressor state. Compressor states are:

STOPPED RUNNING LOADED

ALARM!

Below compressor state light you can see temporary % load of the

compressor. If compressor is VSD and it is running loaded this % changes

from 0-100%. If compressor is ON/OFF and it is running loaded this %

indicates full load (100%). If compressor is running unloaded or is

turned off this % indicates no load (0%)

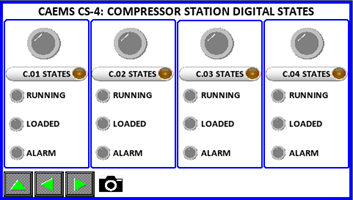

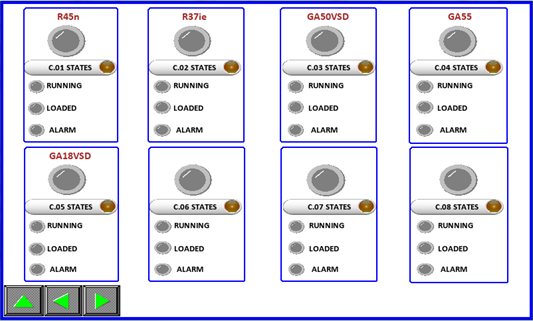

You can navigate the menu by pressing any of the avaliable

buttons. To return to home

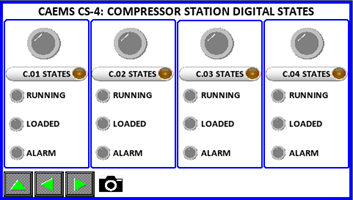

page press the button.Pressing the button will activate the CAEMS

status menu, which is composite by several different pages:On the first

status page compressor digital states are visible.

buttons. To return to home

page press the button.Pressing the button will activate the CAEMS

status menu, which is composite by several different pages:On the first

status page compressor digital states are visible.

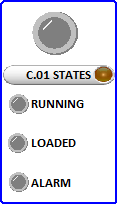

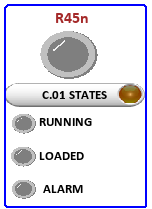

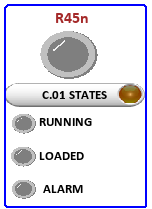

If any state is active, the lights will turn on in color, otherwise the

displayed color is gray. Upper light represent the same states as

in REVIEW page.

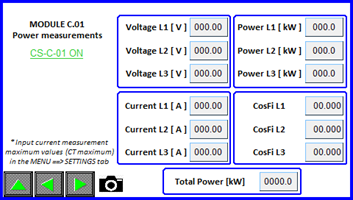

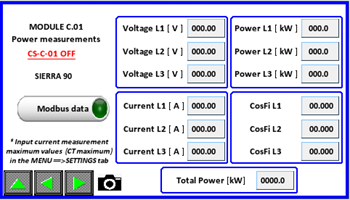

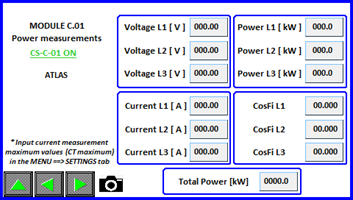

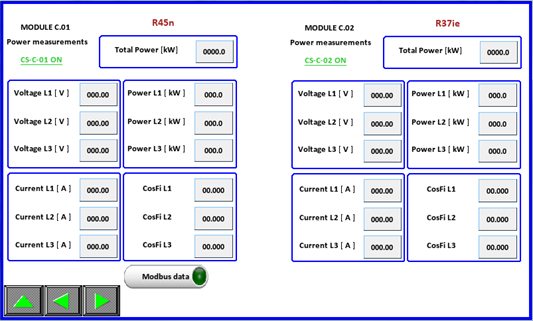

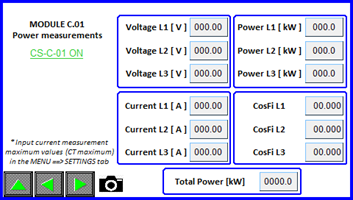

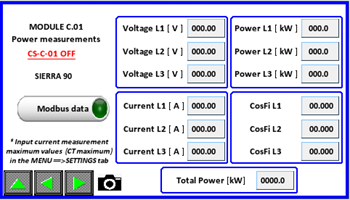

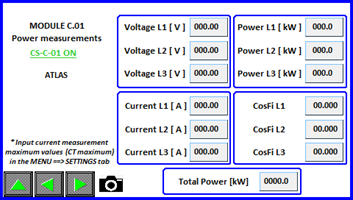

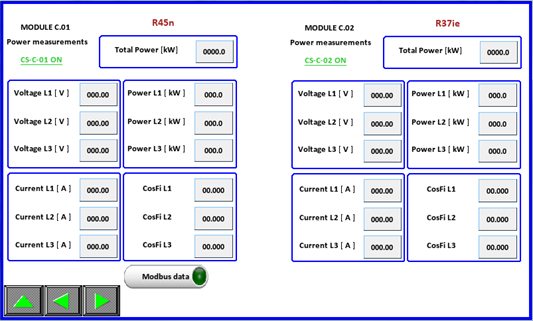

You can jump directly to compressor power analyzer state by pressing the name close to the compressor symbol. On the PM-X there are 4 compressor power measurement pages. Here are displayed power related measured values.Notice the CAL-C-X text . If the text is colored GREEN a CAEMS compressor module is connected and recognized, otherwise the text color is RED!

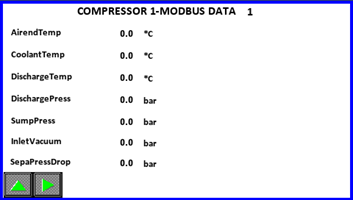

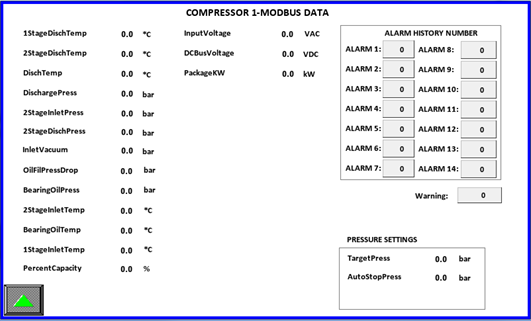

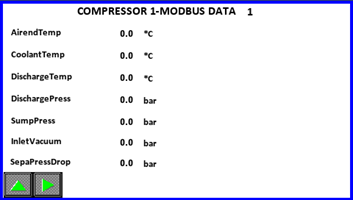

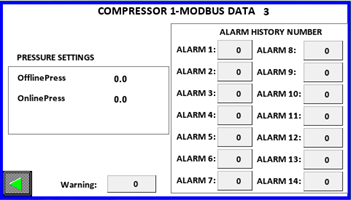

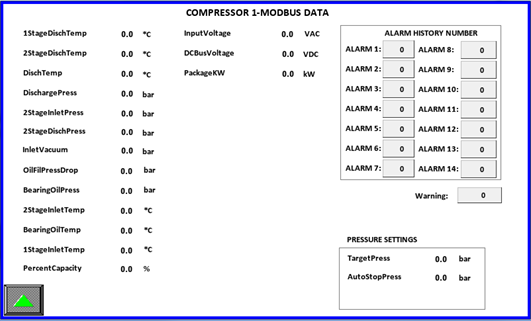

If compressor has enabled MODBUS communication an extra button is

displayed. By pressing this button you enter to compressor MODBUS

parameters pages.

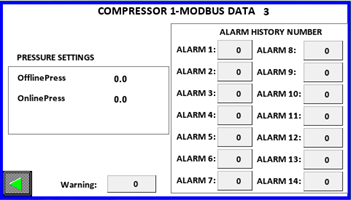

Here are three MODBUS pages. How many parameters is shown depends which

controller is selected. (See belowàCompressor settings). On first page

you can see first 14 parameters.

On last third page you can se pressure parameters, alarm and warning

codes for further analysis

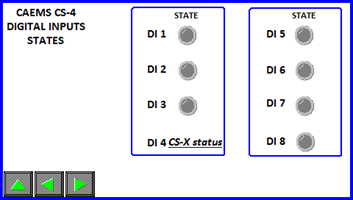

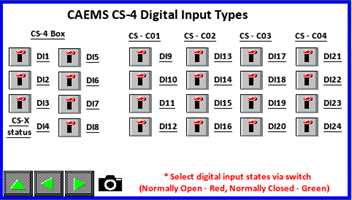

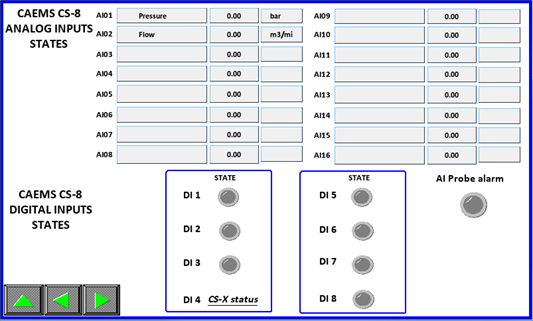

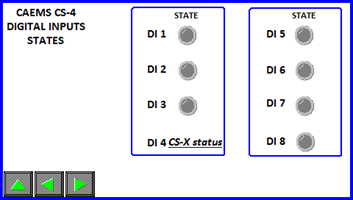

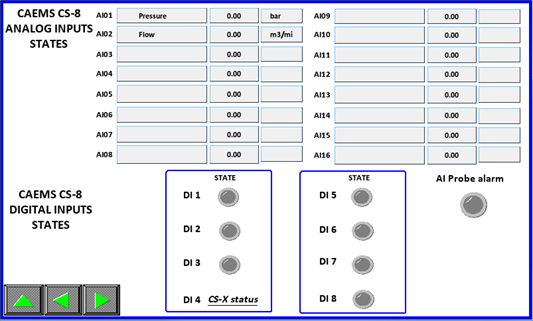

The second page of the CALMS STATUS group represents CALMS PM-X digital input states. Each PM has by default eight digital inputs. If a digital state is active the representing light will light up.

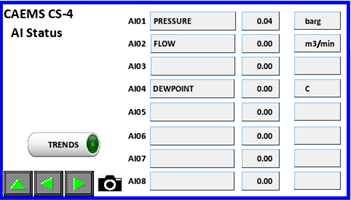

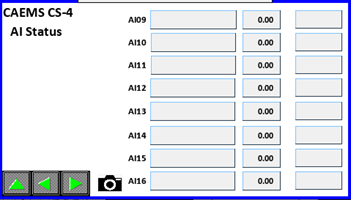

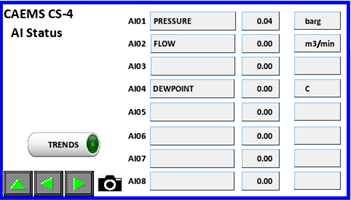

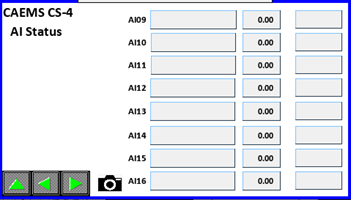

Pressing the up button from this screen will show the main selection

screen, otherwise pressing will show the next/previous screen. The

analog inputs screen displays values that needs to be entered in the

SETTINGS menu. When settings are completely filled, the input tags and

measurement values will be displayed in real time as in picture above.

Here you can also access to TRENDS menu. Moving trough the menu is

achieved by pressing the buttons.

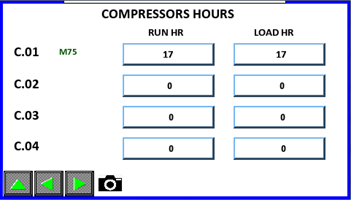

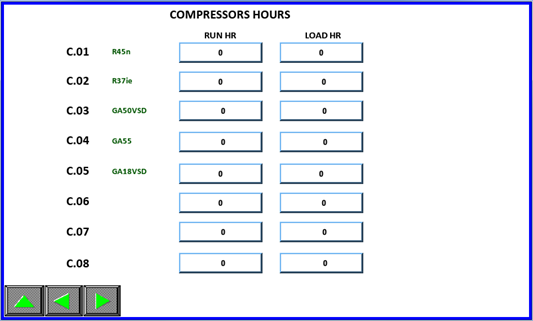

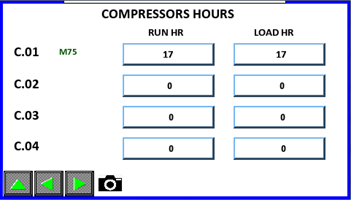

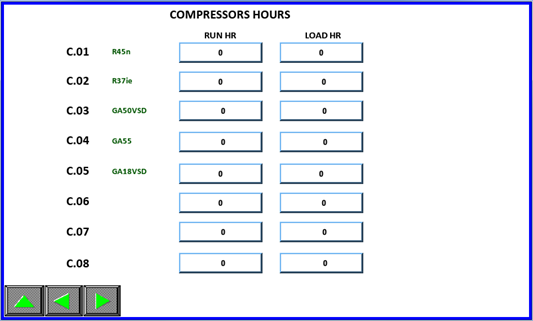

Next page indicates compressors hours. Hours are calculated via running

and loaded signals or via MODBUS states if enabled. The hours can be

corrected by clicking on fields, but you have to be login as manager.

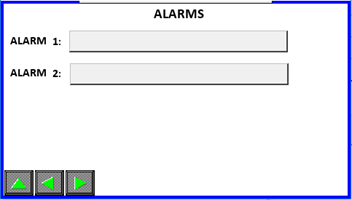

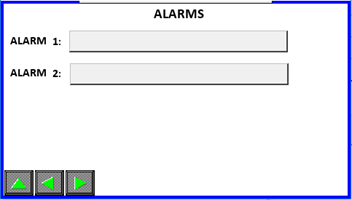

Next page shows us active alarms. If no alarm is present the fields are empty. Possible alarms are:Critical pressure, AI probe alarm, DI alarm, Voltage Imbalance alarm, Compressor 1-8 alarm, C.01 to C.08 alarm and EMCS Fault Compressor 1-8.

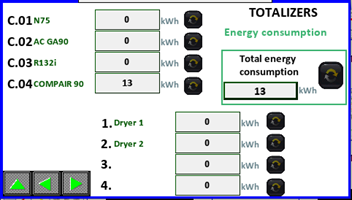

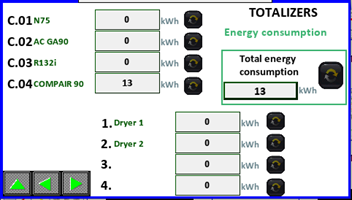

Next page shows energy consumption totalizers. System calculates energy

consumption for each compressor and for additional fourAi’s that can be

selected in CALMS settings (login as operator required). Total energy

consumption is sum up of all compressors and additional 4 AI’s energy

consumptions. You can reset each energy consumption by pressing button

(press and hold for 1 sec, login as operator required).

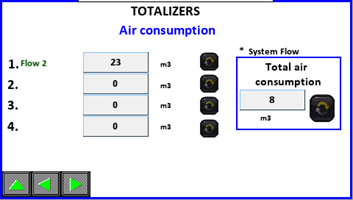

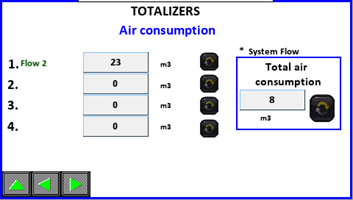

Next page shows air consumption totalizers. System calculates air consumption for selected System flow (this can be selected in CALMS settings Meter display settings, login as operator required) on HMi visible as Total air consumption and also calculates totalizers for additional four Ai’s which are calculated independately of total air consumption. (if you have flowmeter installed on one of production lines and you want to know what is the air consumption of this line, you select this AI as additional AI for air consumption totalizer)

Next page will display MODULE C.01 power management, next MODULE C.02

power management and so on ..

Returning to the REVIEW page is done by pressing the up button.

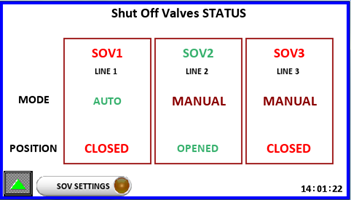

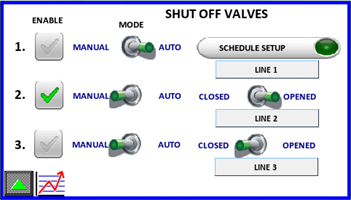

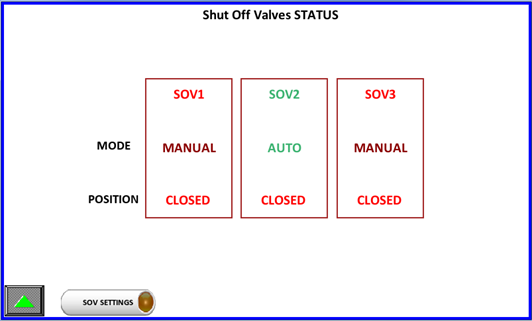

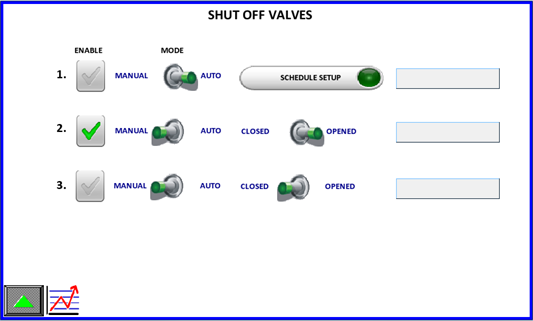

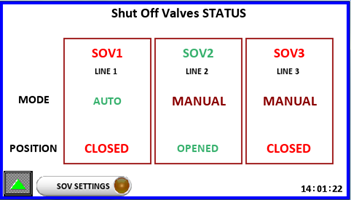

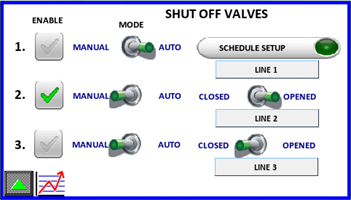

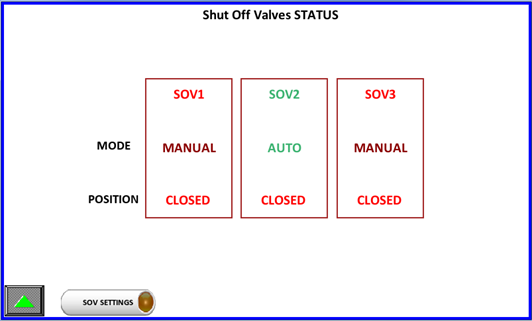

By clicking on you will enter the Shut Off Valves status menu. NOTE:

This feature must be enabled to be possible to enter those status

menus.Here you can see statuses of all three SOV. Red or green color of

specific valve ( , ) tells us if specific SOV is enabled or disabled.

Red color means that this SOV is disabled (its regulation is disabled),

green color means that this SOV is enabled (its regulation is

enabled).Each SOV is recognized through “SOV Name” which is given in SOV

settings (must be logged in as Operator). Each SOV can be in AUTO or

MANUAL mode. Manual mode means that valve can be opened or closed via

HMI interface by switching the Open-Close switch. If SOV is in AUTO mode

means that valve is opening, closing via schedule which is set on daily

base.Position of SOV indicates the position of specific SOV.

Returning to the REVIEW page

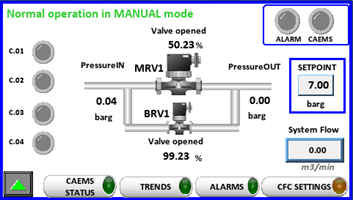

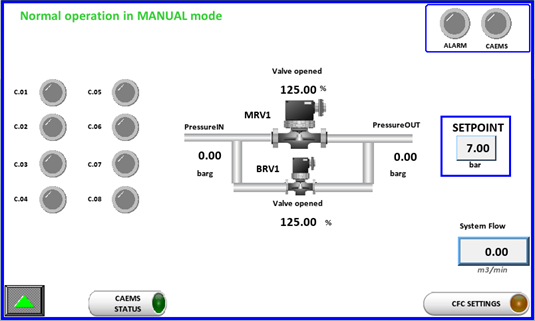

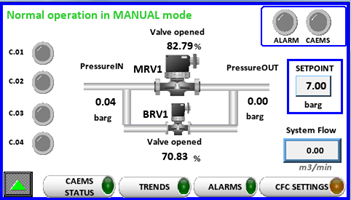

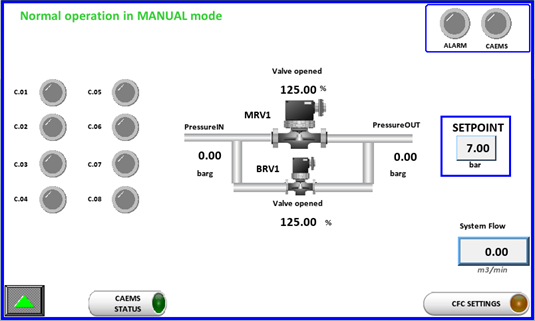

is done by pressing the up button. By clicking on you will enter the

CFC Status page. NOTE: This feature must be enabled to be possible to

enter those status menus.

Returning to the REVIEW page

is done by pressing the up button. By clicking on you will enter the

CFC Status page. NOTE: This feature must be enabled to be possible to

enter those status menus.

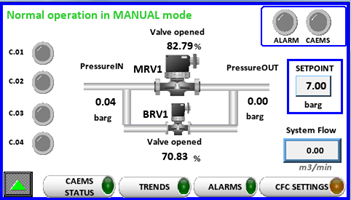

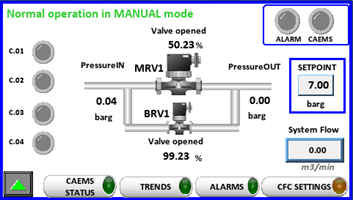

On CFC Status page we can see all the vital system and CFC

parameters.(Statuses of compressors, position of CFC valves, Inlet and

Outlet pressure, Setpoint value and System flow. On the top of the

window is a status bar which indicates if which regulation mode CFC is.

Here is in MANUAL mode. That means CFC valves can be regulated manually

via HMI interface in CFC Settings (must be logged in as operator).

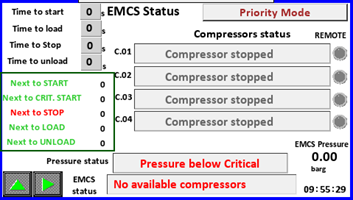

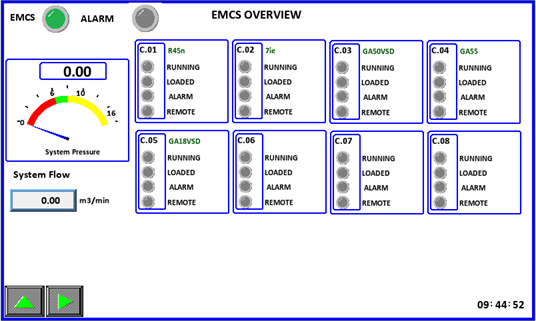

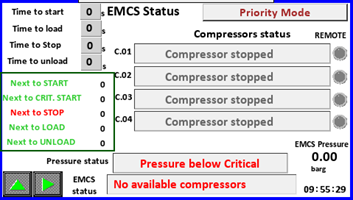

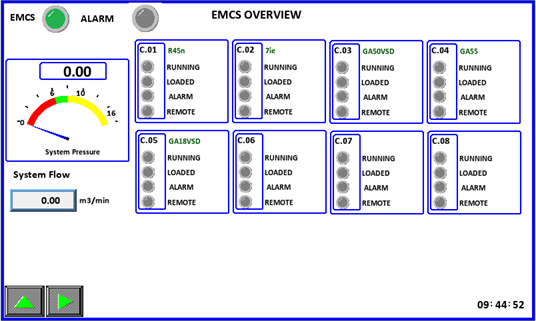

Returning to the REVIEW page is done by pressing the up button. By

clicking on you will enter the EMCS Status page. NOTE: This feature

must be enabled to be possible to enter those status menus.On first EMCS

status page you can see all the compressors states (Compressor stopped,

loaded, unloaded, alarm, remote control enabled). You can also see what

is the pressure status and what is the ECMS status. EMCS status tells us

what EMCS function is doing, for example: loading new compressor,

starting new compressor,…On the top right corner we can see what is the

enabled control mode (Priority mode, Energy mode or Schedule mode).

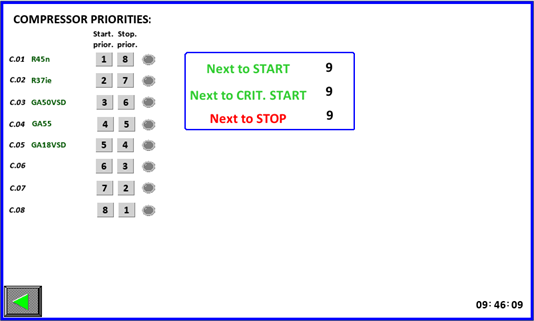

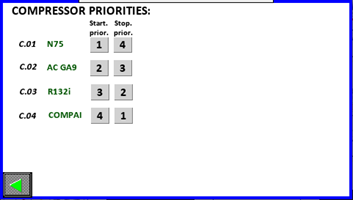

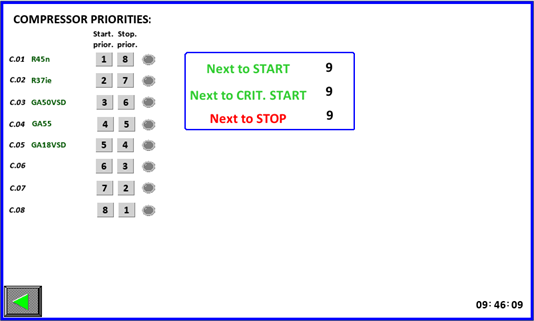

You go to next page by clicking icon. On next page you can see actual

compressors stop and start priority.

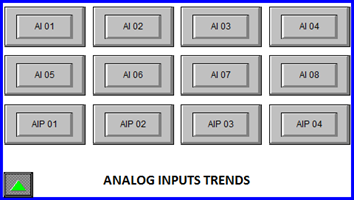

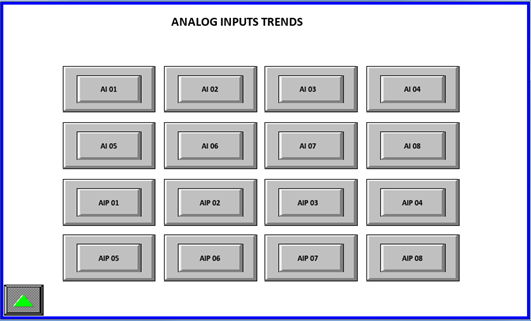

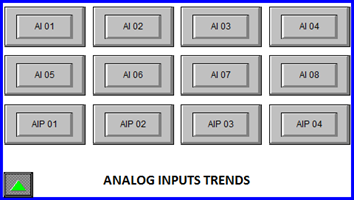

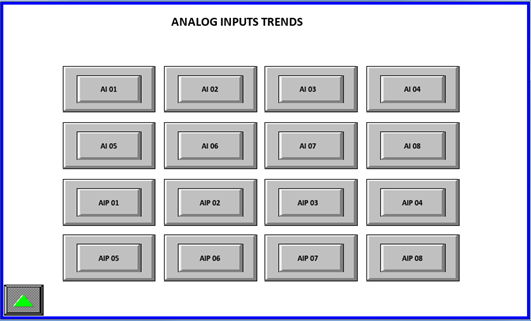

TREND SCREEN

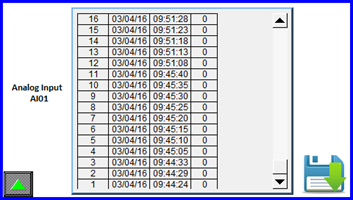

By pressing the button it will show the Analog inputs trends screen.

Here you will be able to investigate a single AI values at desired

time. Pressing the up button from this screen will show the main

selection screen.

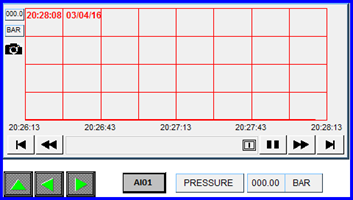

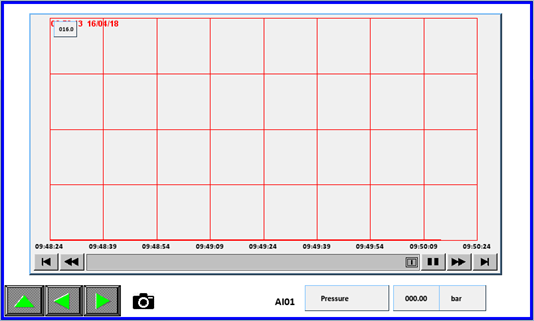

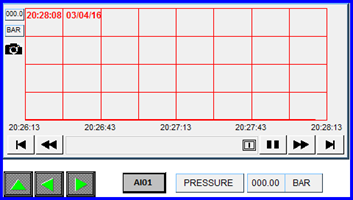

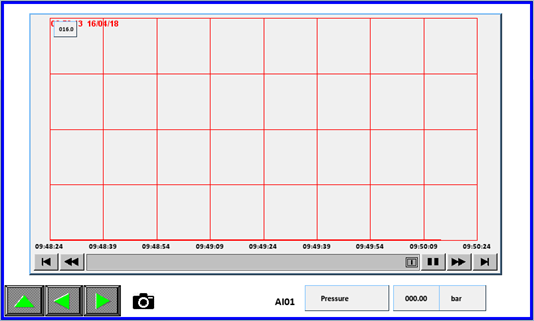

When any AI0X button is pressed the following screen will be shown

:

Pressing the up button from this screen will show the TRENDS selection

screen. Buttons will move to previews/next analog input trends. In the

upper left corner you will find a camera icon . Pressing it will save a

print screen of the opened page. Right to the forward button is

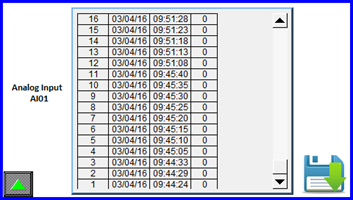

displayed the analog input number/name . Pressing it will open a history

window from witch you will be able to safe a csv file of the input

values by pressing the save icon ( save to USB if present ).

Returning to the main selection screen is performed by repetedly

pressing the up button.

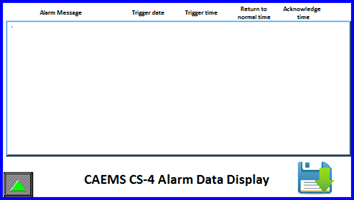

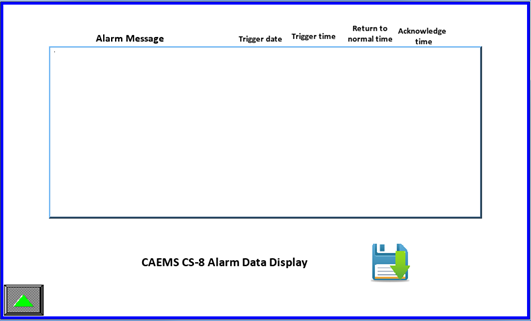

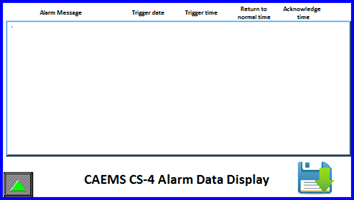

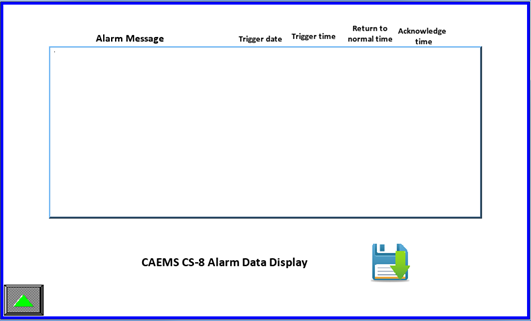

ALARM SCREEN

By pressing the button will show the ALARM screen

Here you will be able see any alarm that has been recorded by the CALMS

system. Alarms must be acknowledged by pressing on the alarm text (text

color with turn to green). Pressing the up button from this screen will

show the main selection screen

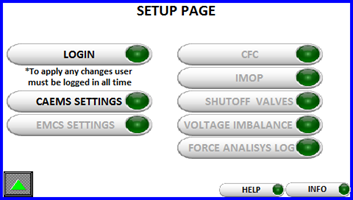

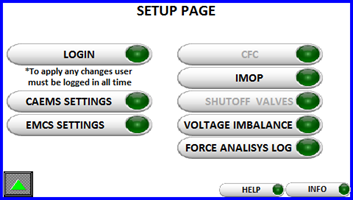

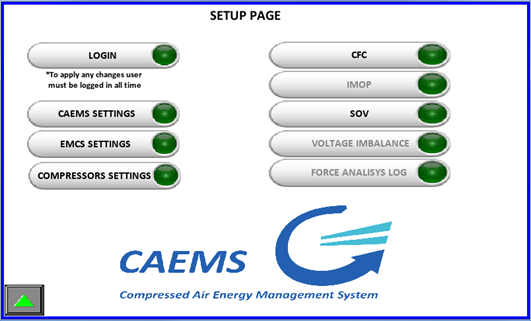

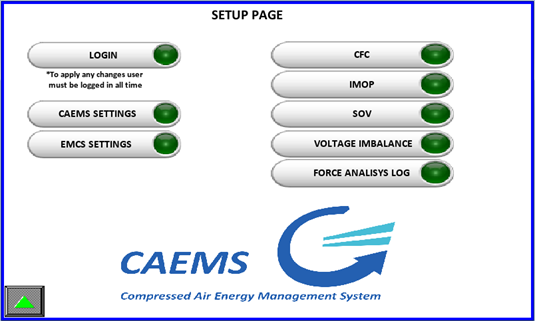

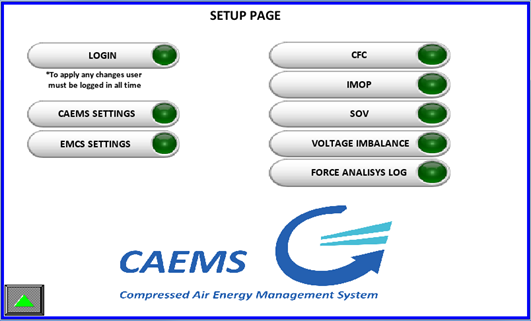

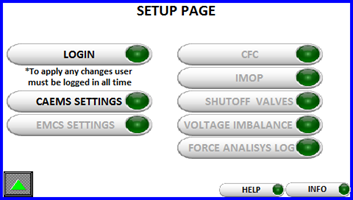

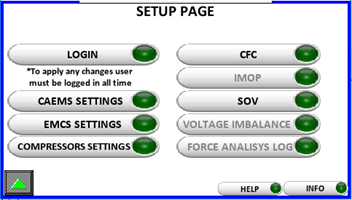

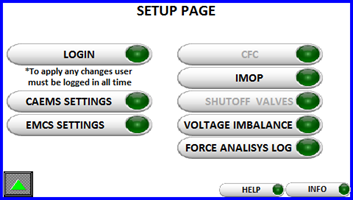

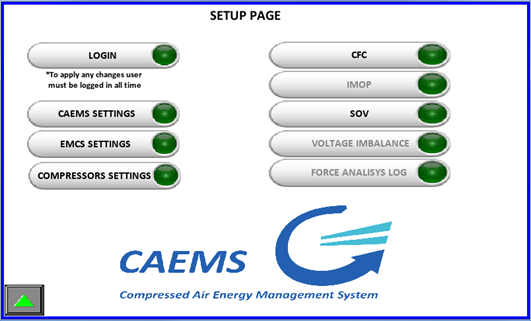

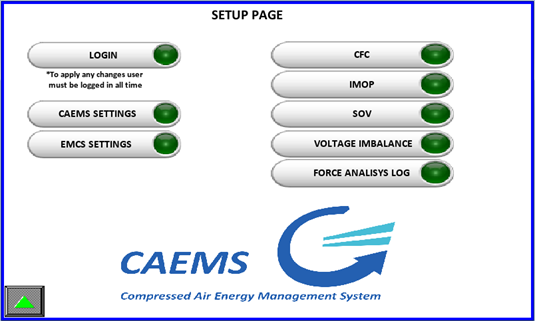

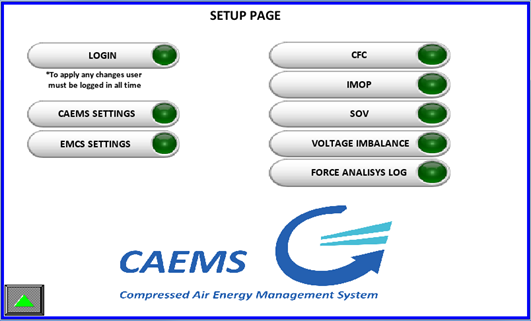

SETUP

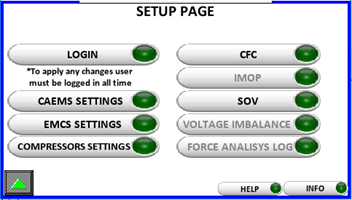

Next on the main window is the SETUP icon . Pressing it will show the

SETUP page.

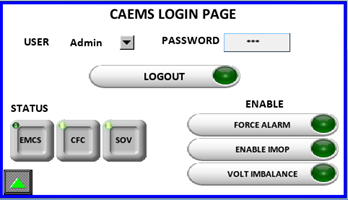

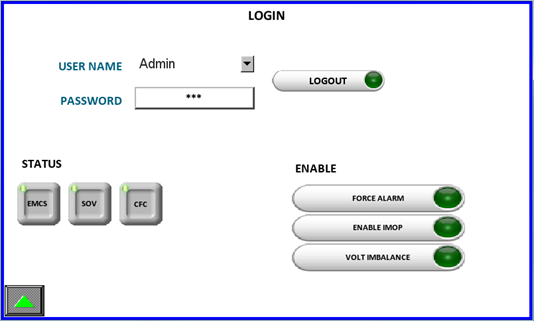

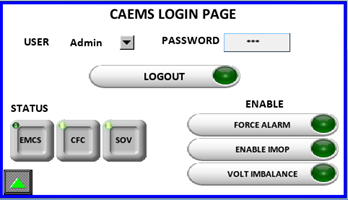

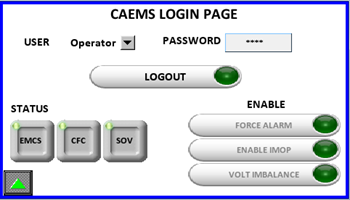

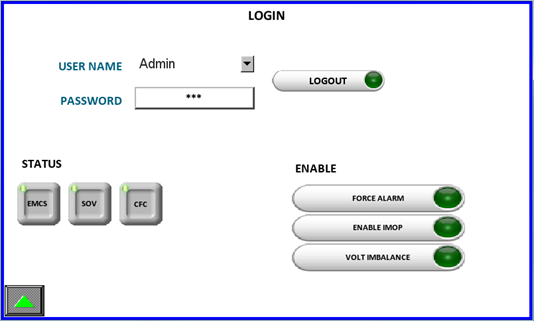

LOGIN SCREEN

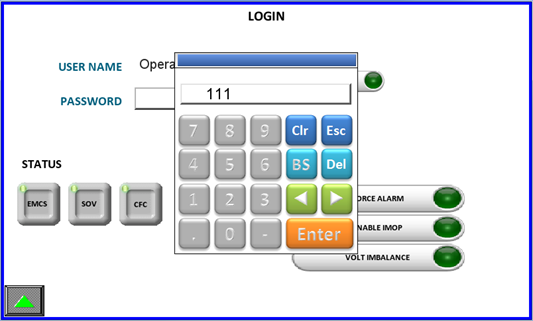

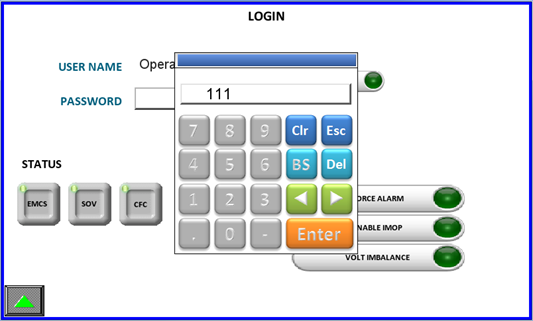

Before you can actually enter or enable any setting a operator login is

mandatory. This is done by the following procedure.By pressing the

button in the main manu you will be showed the login screen. Here you

can see which functions are purchased and

enabled.

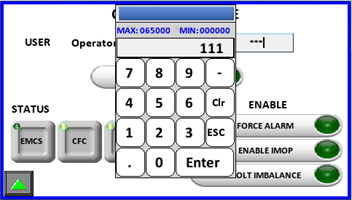

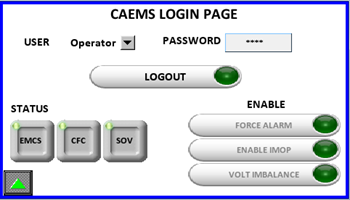

Operator is to be select by a dropdown menu,

Password is to be inputed by user. Prior to that any change is

uneditable.

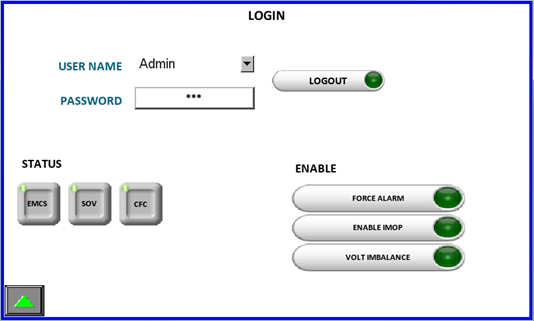

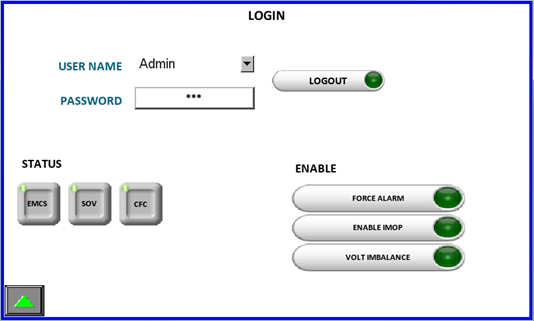

After succcesfull login additional options can be enabled. Enabling the

option will be seen by activity light and text change. Please notice

that not all option are avaliable. Which options will be avaliable is

determined by the option your CALMS is shipped. In the picture below

CFC,EMCS and SHUTOFF VALVE options are purchased therefore are all

avaliable to use.

Pressing the up button from this screen will show the SETUP screen.

After enabling additional options the SETUP page menu looks different:

CALMS SETTINGS SCREEN

By pressing the button will show the SETTINGS screen. There are several

screens where you can input system settings.

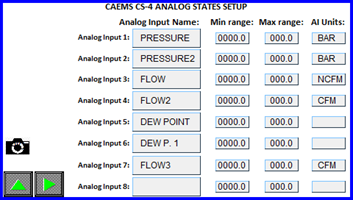

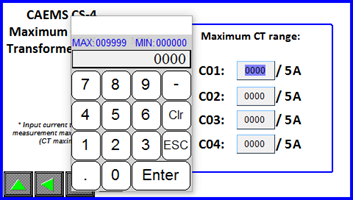

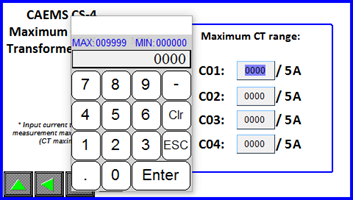

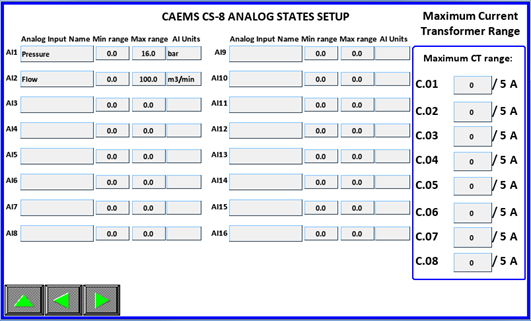

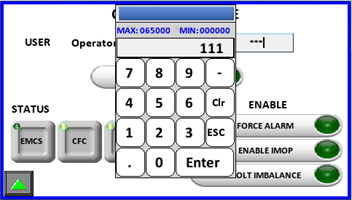

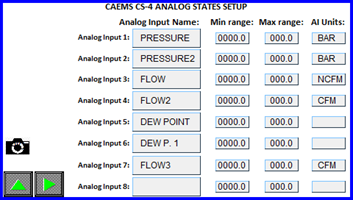

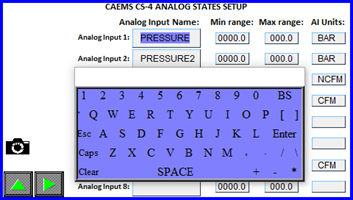

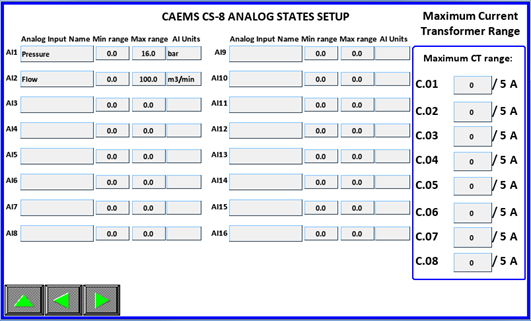

CALMS PM-X ANALOG STATES SETUP

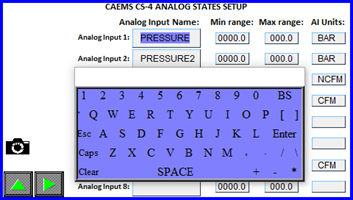

Here you MUST input Analog inputs name, min values, max values and

measuring units. Pressing on an empty box under Analog input name or AI

Units opens a keyboard.

After entering desired text press the Enter button to confirm input and

hide keyboard, or ESC to cancel inputs and hide keyboard. Pressing the

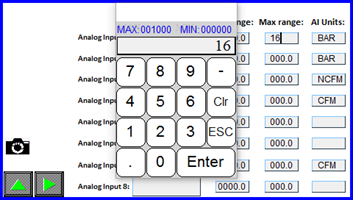

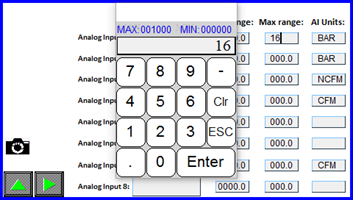

gray button under the Minimum or Maximum AI range will open a numerical

keyboard for entering numerical

data.

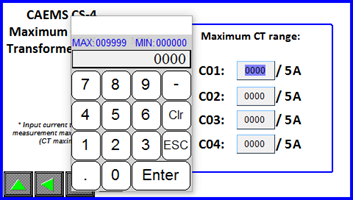

Current transfomer range must be entered here for each CAL-C module (Compressor). Buttons in the lower left corner still have the same functionality as on other screens.

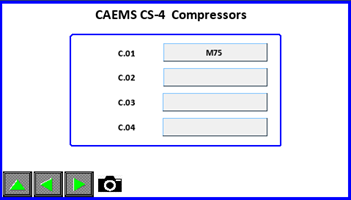

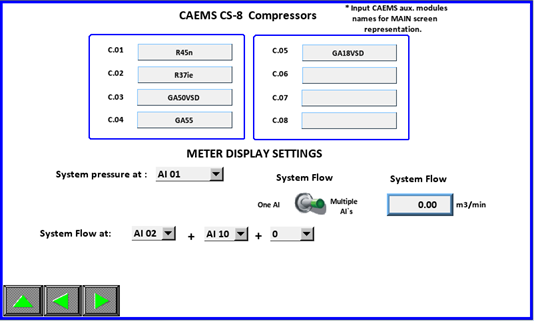

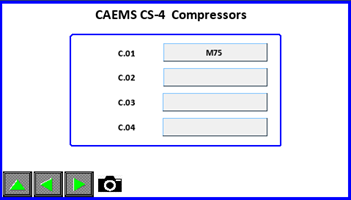

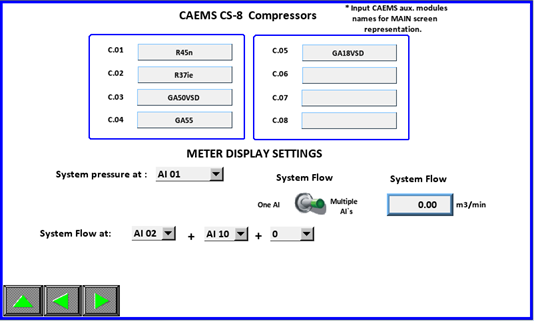

COMPRESSOR NAMES

Compressor names can be given names through this input page.

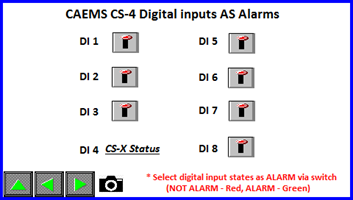

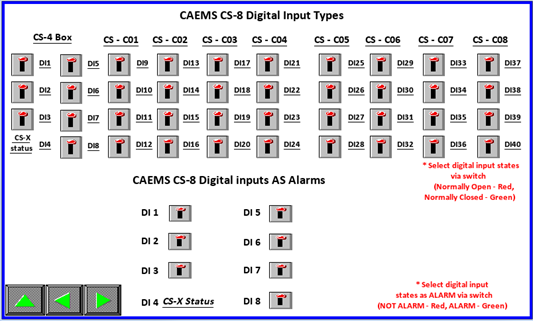

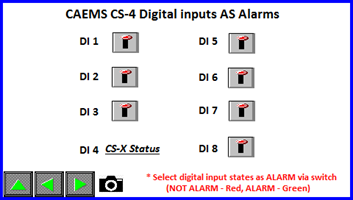

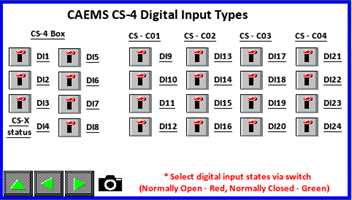

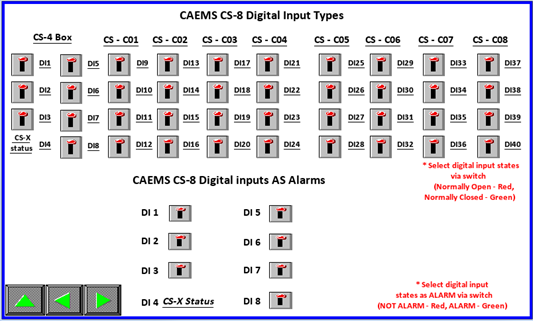

Here you can choose which DI`s you will use as ALARM inputs. If

specific DI is used as ALARM means that after 5s of active state alarm

output DO4 will be activated and also CALMS Alarm will be triggered.

Depending on what type of digital input you need (NO, NC) different

inputs states and logic can be selected here. Here you can set for all

DI’s that are available in your device.

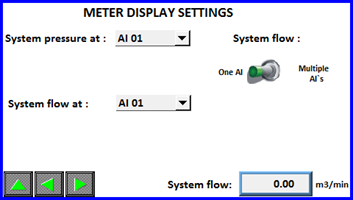

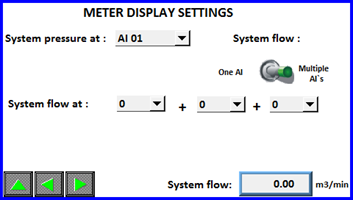

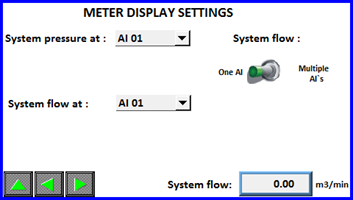

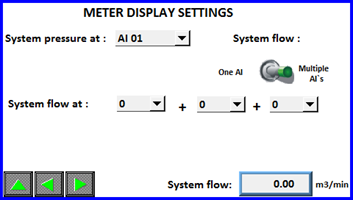

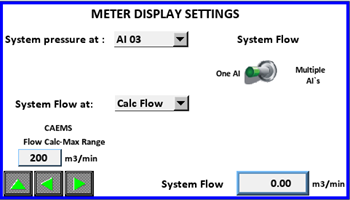

METER DISPLAY SETTINGS

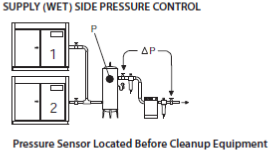

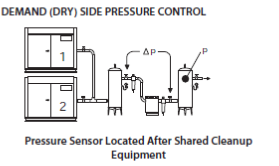

Here you can choose, depending on which AI is your system pressure, the

correct AI. Same for system flow. In case system flow is on multiple

AI`s you select “Multiple AI`s” and choose correct analog inputs. Sum

of all AI`s is your system flow from which Specific power is

calculated.

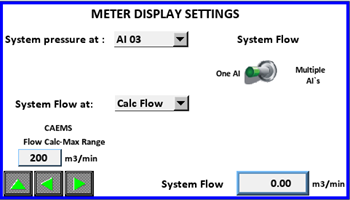

If you don’t have connected flowmeter to any of AI’s you can choose

“Calc Flow” and system will calculate the flow. In this case nominal

flow of compressors must be set correctly, otherwise calculation of flow

will not be correct. Here you can also check what is the MAX RANGE of

calculated flow. Default value is 300 m3/min. If necessary it can be

changed, but you have to be login as Manager. This MAX Range value is

value which is set on CALMS WEB interface as MAX Range of AI21. (AI21 is

reserved for calculated

flow)

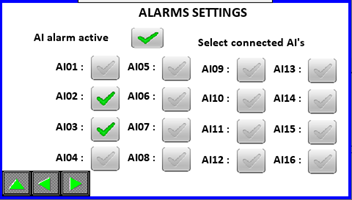

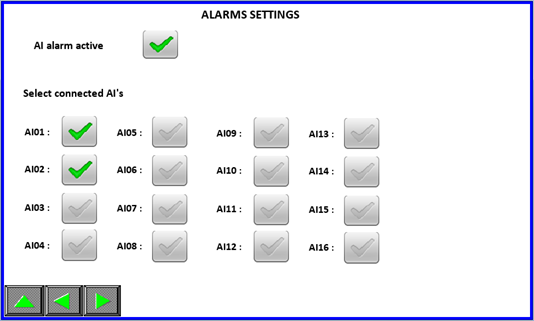

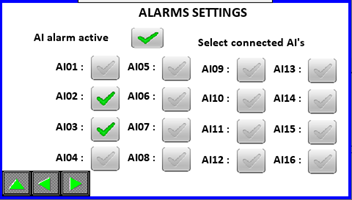

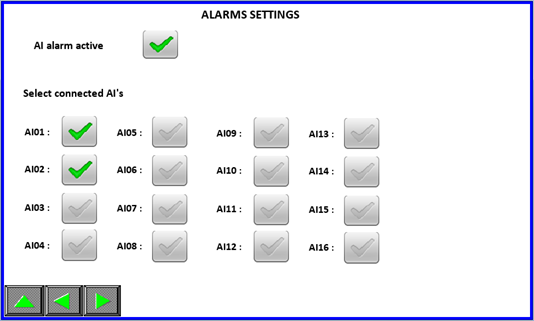

ALARM SETTINGS

Here you can choose which analog inputs are connected to 4-20mA sensors.

System will than constantly checking those inputs. In case of under or

over current of the analog input alarm will be triggered.

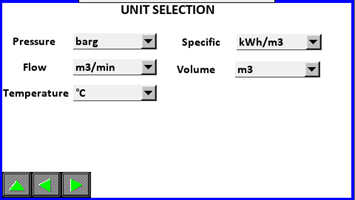

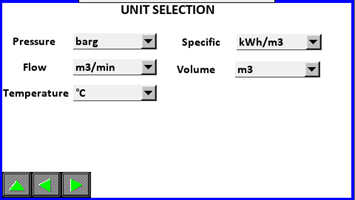

UNIT SELECTION

On unit selection page you can adjust units for pressure, flow,

specific, temperature and volume. This settings must be set correctly

and same units must be used on analog input settings page, because

system is doing some calculations based on those

settings.

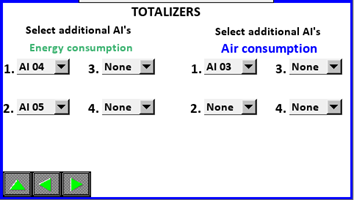

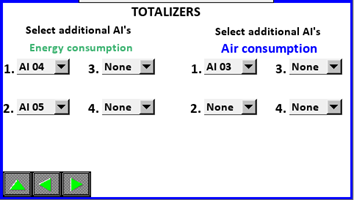

TOTALIZERS

On this page you can adjust four additional analog inputs for totalizer

calculation. Adjust four additional AI’s for energy consumption which

will be added to total energy consumption ( compressors energy

consumption + additional AI’s energy consumptions = total energy

consumption). Adjust four additional AI’s for air consumption, which are

independently calculated and have no relation with total air consumption

which is based on system flow measurement. If none is selected means

that system will not calculate certain additional

TOTALIZER.

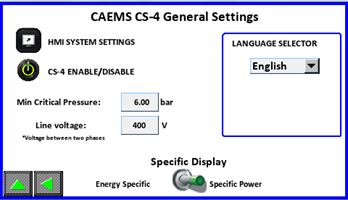

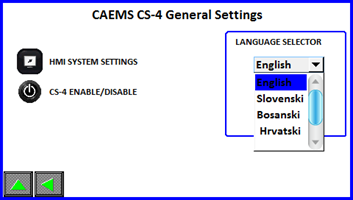

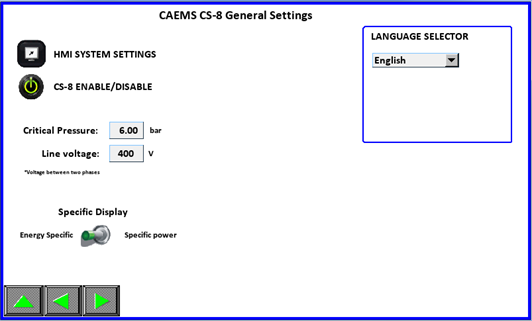

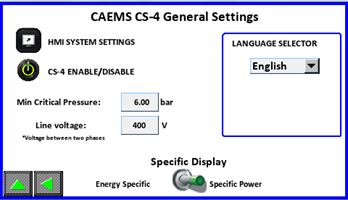

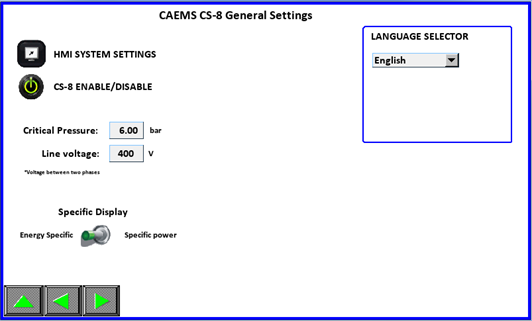

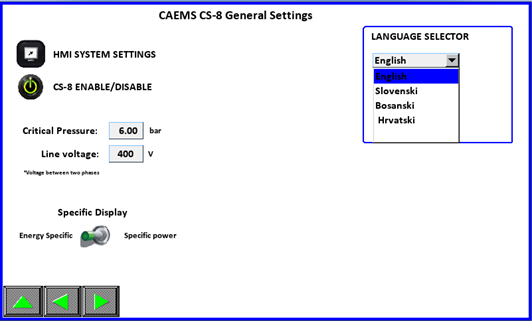

GENERAL SETTINGS

Here you can acess the HMI setting page and enable or disable the PM-X functionality.Minimal critical pressure is used to automatically set PM-X ENABLE/DISABLE button to off if pressure is under that value and all compressors are shutdown. Line voltage setting is used for power calculation ( see below). You can also choose energy specific display or power specific display.

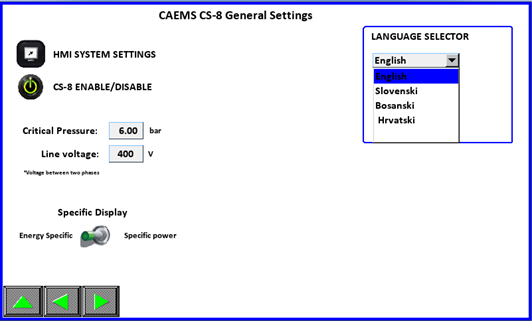

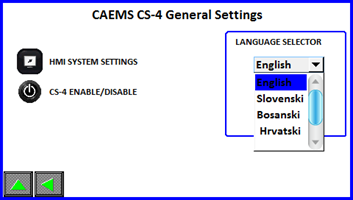

On this page users can select HMI display language by language selector

:

Depending on user location and expected language the selection can be

upgraded. After finishing the setting up of the input return to SETUP

page by pressing the button.

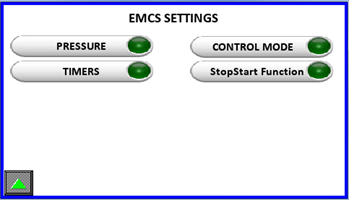

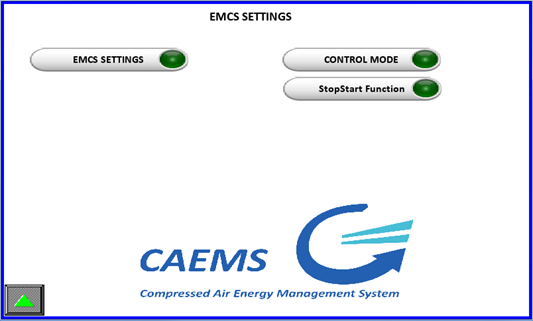

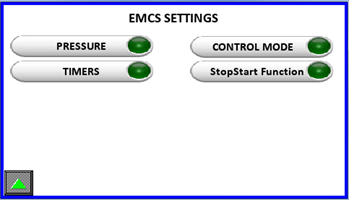

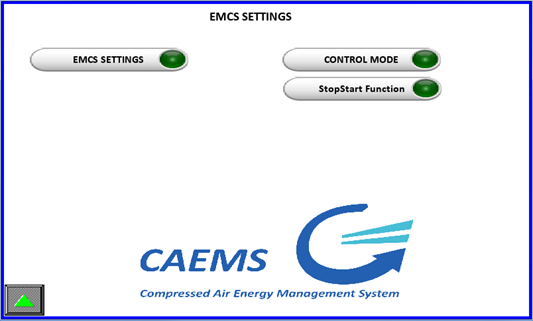

EMCS SETTINGS

If EMCS is purchased and enabled in login page you can acess EMCS

SETTINGS by pressing the EMCS SETTINGS button and a setup screen for

the control system will be displayed. Here you can input EMSC options

such as control pressure, timers and control

mode. Navigate the pages with

the navigation buttons as usual.

Navigate the pages with

the navigation buttons as usual.

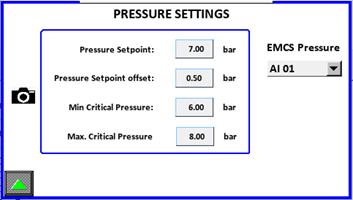

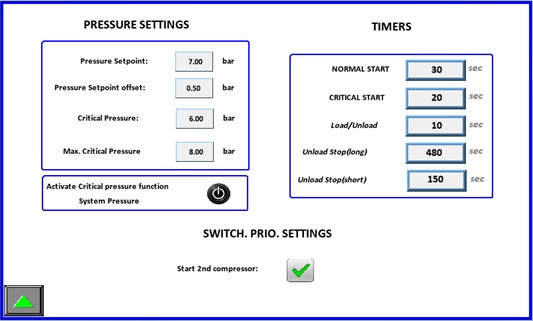

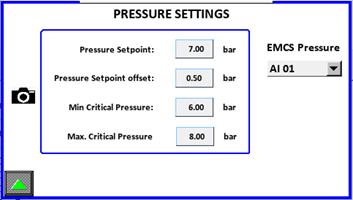

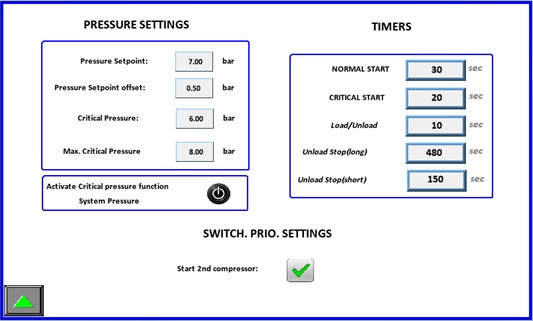

PRESSURE SETTINGS

On this page user setups EMCS pressure parameters.PRESSURE SETPOINT:

is the desired pressure of the systemCRITICAL PRESSURE: is the

minimum pressure of the system. If pressure goes below that point an

alarm will be issued and additional compressors will be

started.PRESSURE SETPOINT OFFSET: is the below and under Pressure

Setpoint setting. If pressure reaches (Pressure Setpoint + Pressure

Setpoint Offset) next compressor will be unloaded and if pressure

falls below (Pressure Setpoint - Pressure Setpoint Offset) next

compressor will be loaded.MAX. CRITICAL PRESSURE: If pressure

reaches this set value emergency stopping of compressors is followed.On

this page you can also select on which AI is connected pressure sensor

for EMCS regulation.

If pressure settings are setup as above the EMCS will try to maintain a

system pressure between 7,5 and 6,5 bar. If pressure goes higher

compressor will be unloaded, if pressure falls below next compressor is

loaded.

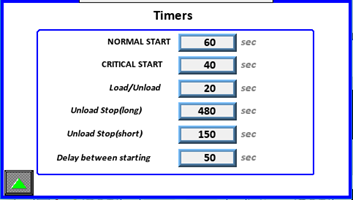

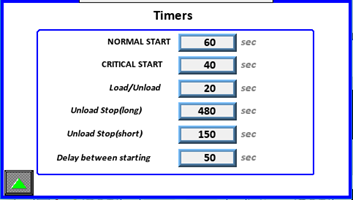

TIMERS

On this page user setups EMCS TIMER settings:NORMAL START: time that

EMCS will wait before starting compressor in the system if system

pressure falls below (Pressure Setpoint - Pressure Setpoint

Offset).CRITICAL START: time that EMCS will wait before starting

another compressor if system pressure falls below critical pressure set

pointLoad/Unload: time that EMCS will wait before loading or

unloading next compressor.Unload Stop(long): time in which next

unloaded compressor will be stoppedUnload Stop(short): time in which

next unloaded compressor will be stoppedDifference between long/short

timer is in the number of unloaded compressor. If only two or less

compressors are unloaded than long timer is used, otherwise short timer

is used.Delay between starting: time that EMCS will wait unit

starting next compressor (normal and critical conditions)

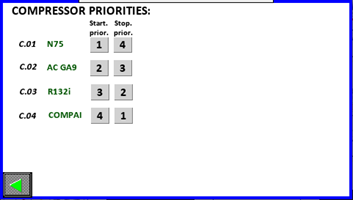

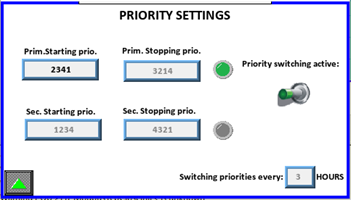

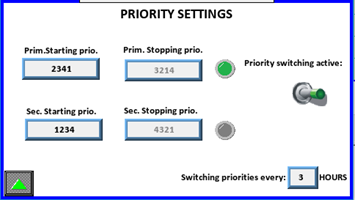

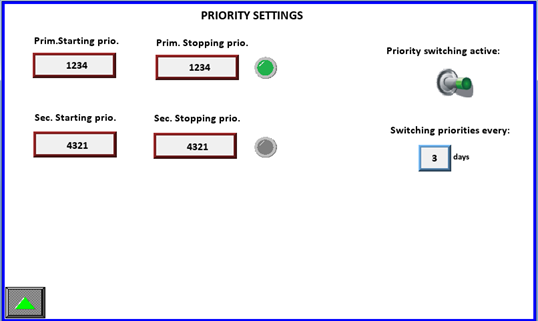

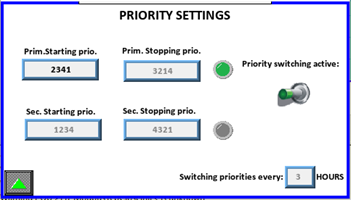

IMPORTANT! PRIORITY MUST NOT BE SET AS ZERO. TWO COMPRESSOR CAN’T HAVE

SAME PRIORITY NUMBER!!!Compressor with the HIGHEST starting priority

number will be started FIRST, compressor with LOWEST starting priority

number will be started last.Compressor with the HIGHEST stopping

priority number will be stopped FIRST, compressor with LOWEST stopping

priority number will be stopped last.

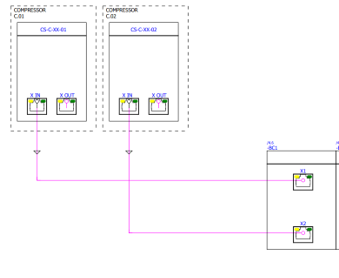

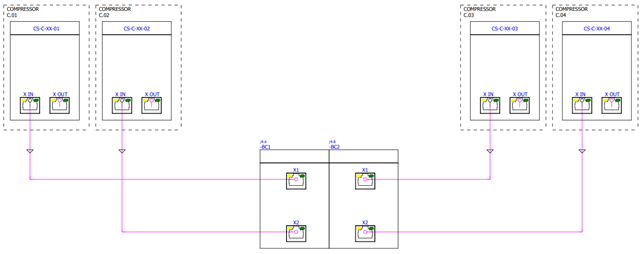

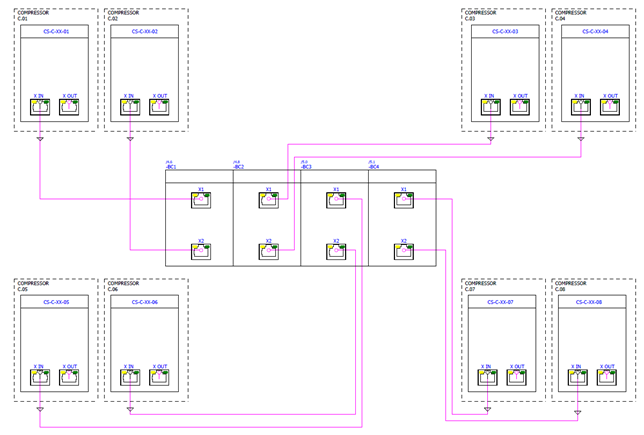

EXAMPLE: PM-4 Each priority consists of 4 digits ( PM-4) or 8 digits (CS-8). First digit represents priority number of first compressor (C.01) in the system, second digit represents second compressor (C.02) in the system, third digit represents third compressor (C.03) in the system, fourth digit represents fourth compressor (C.04) in the system.** Starng priority: 234Stopping priority**: 2143In upper

example compressor four (C.04) is first to be started/loaded and

compressor three (C.03) is last (fourth) to be started/loaded. When we

are unloading/stopping compressor and we refer on upper stopping

priority we see that compressor two (C.02) is first to be

stopped/unloaded and compressor three (C.03) is last (fourth) to be

stopped/unloaded.

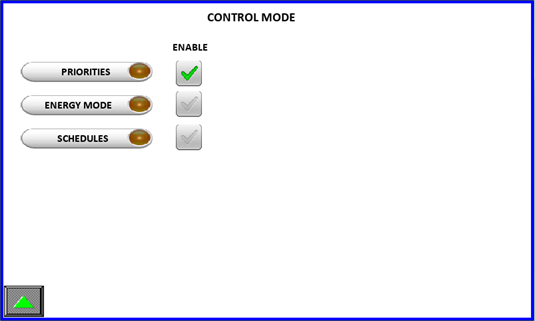

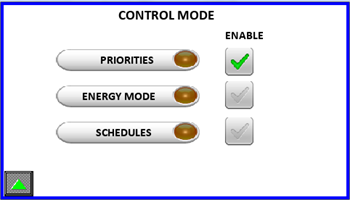

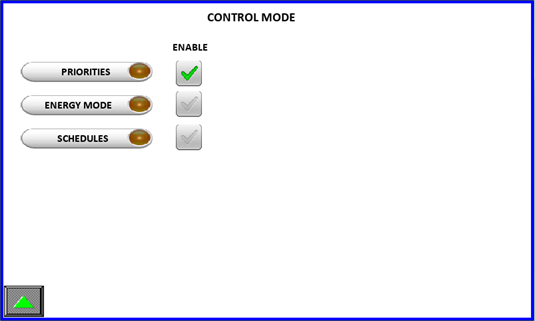

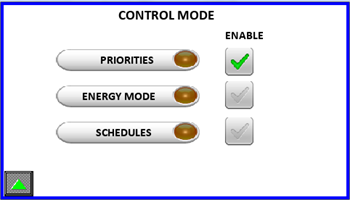

CONTROL MODE

Here you select desire control mode. Only one mode can be selected. You

can adjust settings of control mode by clicking on specific icon. You

can click the icon before enabling specific control mode.

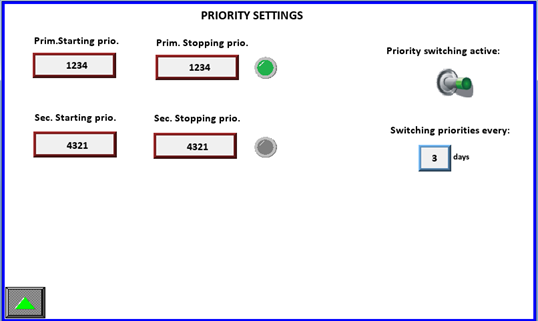

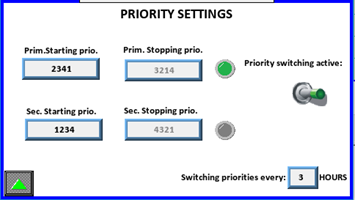

PRIORITIES

In this control mode you have two possible options. One option is to

adjust only Primary Starting Priorities and Primary Stopping

Priorities. You can also enable Switching Prio option and system

will then change the compressors priorites every defined hours.The LED

shows us which priorities are used at the momentàPrimary or secondary.

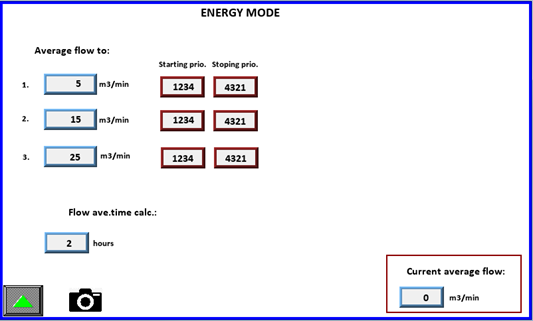

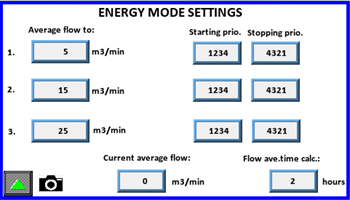

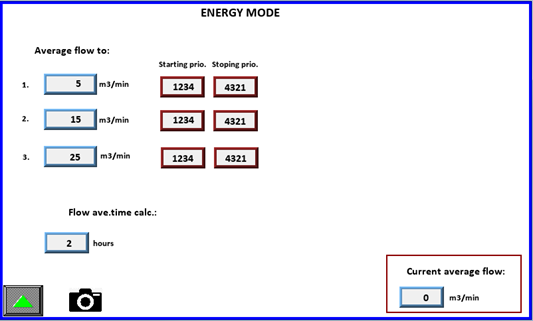

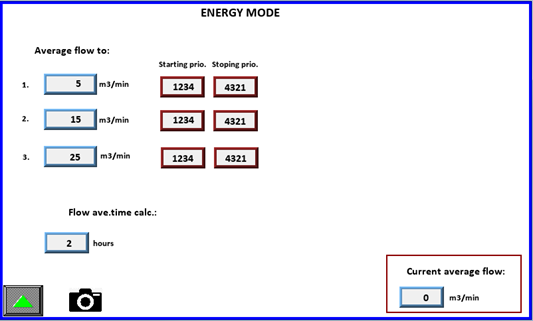

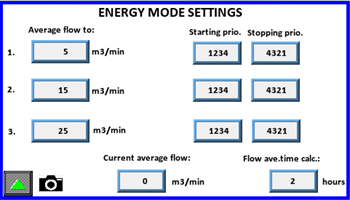

ENERGY MODE SETTINGS

Input your flow values and priorities will be acceppted if system flow

is in determined range. Determine the flow average time calculation.

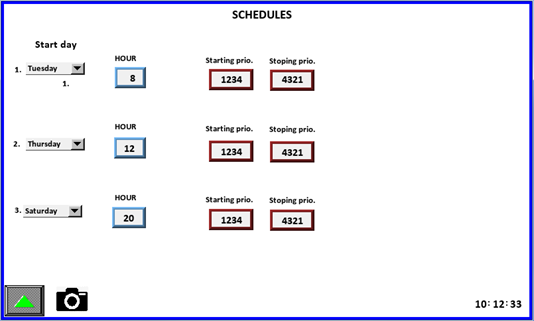

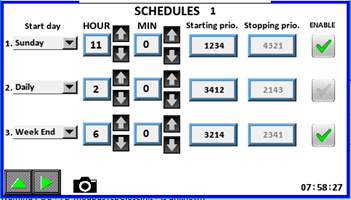

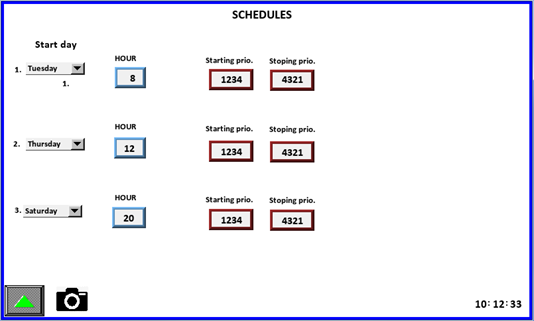

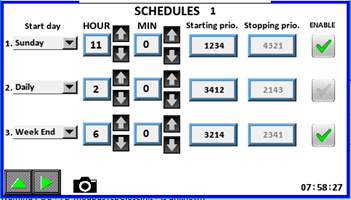

SCHEDULES

You can input nine different schedules. When specific schedule is active

the correct priorities will be accepted. Operator can set the start day,

hour, min, starting priorites and optional stopping priorites. With

enabling certain schedule the system will start using those

settings.** START DAY:** Operator can choose from Monday, Tuesday,

Wednesday, Thursday, Friday, Saturday, Sunday, Daily, Week Day

(Monday-Friday), Week End (Saturday, Sunday).HOUR: 0-23 (can only be

sleected by )MIN: 0-59 (can only be selected by )If two schedules

have the same start day, hour and min the higher numbered schedule

will have priority.

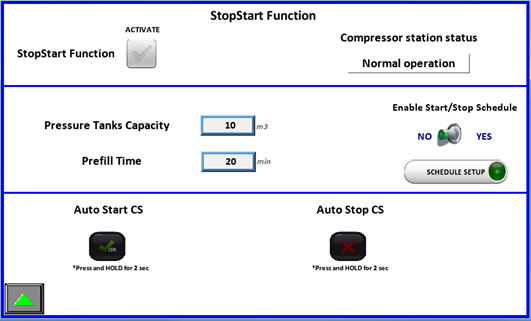

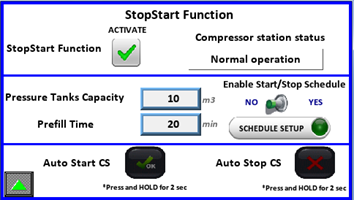

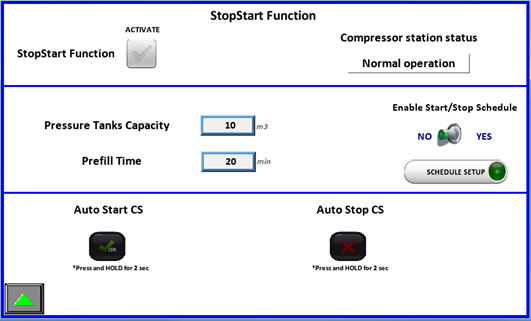

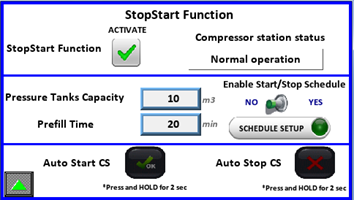

Compressor System Stop-Start FUNCTION

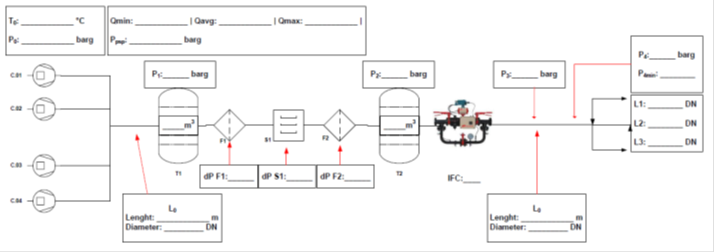

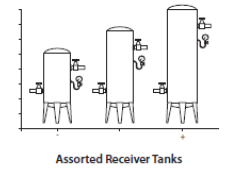

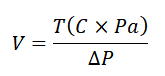

On this page user can stop and start whole COMPRESSOR SYSTEM (CS). By activating this function system will calculate how many compressors are needed to fill the system in prefill time specified by operator. So, when “Auto Start CS” button is pressed, system starts compressors ( how many is calculated from “Pressure tank capacity” and “Prefill time”). When pressing “Auto Stop CS” all compressors will be stopped and system will wait for next command to start CS.

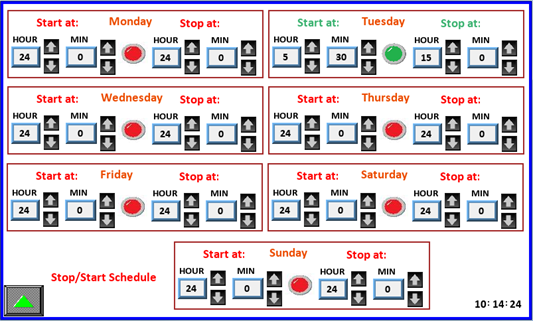

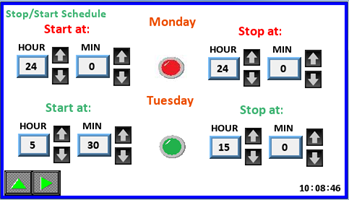

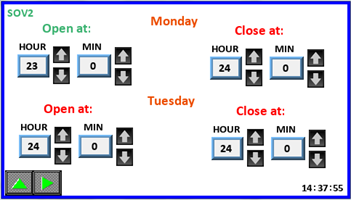

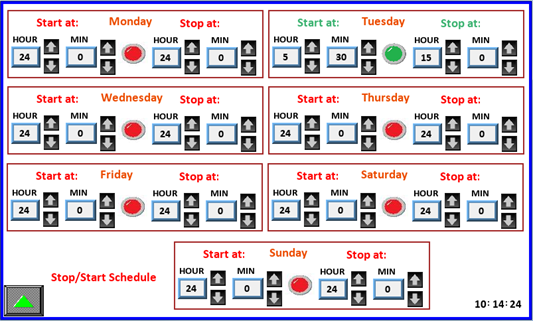

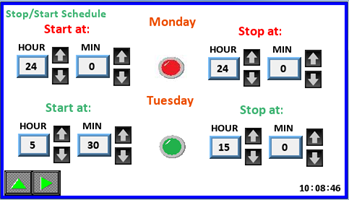

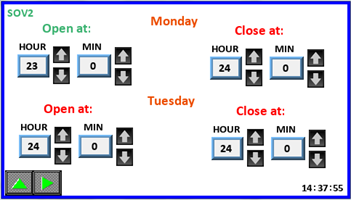

If Start/Stop schedule is enabled, operator has option to adjust

schedule when CS will start and when stop. On picture below we see that

schedule for Monday is disabledàRed LED (If hour for start and stop is

24 then schedule for this day is disabled). For Tuesday we see that

schedule is enabledàGreen LED and time is set. Compressor station will

start at 5.30 and stop at 15.00.Here you can adjust schedule for each

day.

After finishing setup return to the SP page by pressing the UP button.

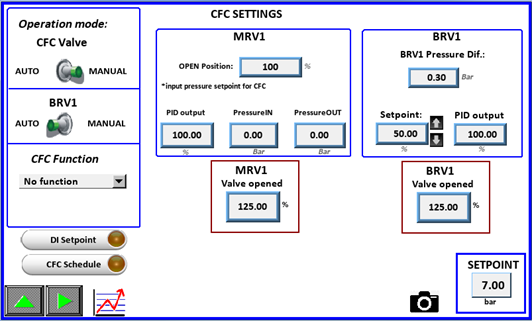

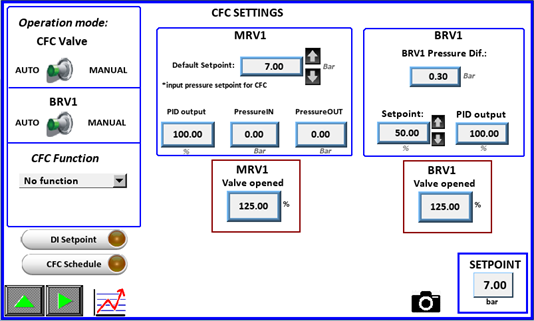

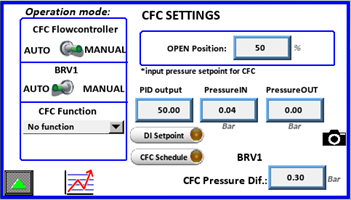

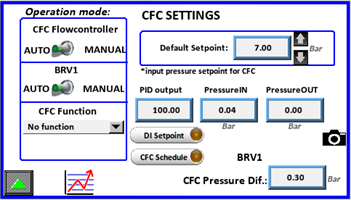

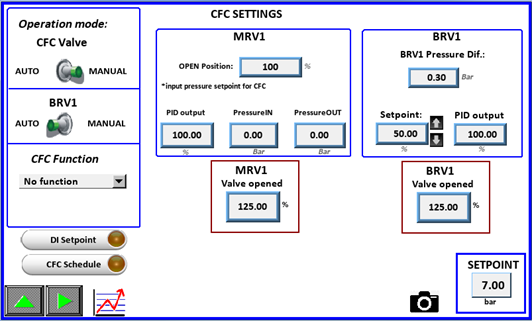

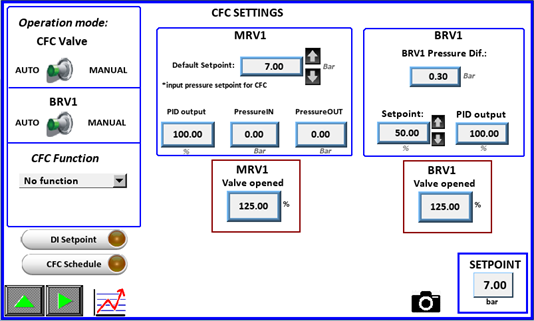

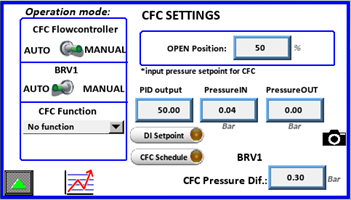

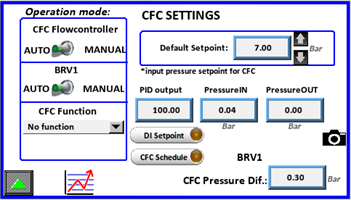

CFC SETTINGS

From the SETUP PAGE, if the option is purchased and enabled pressing the

button enters the CFC menu.Here is the main setting page for CALMS

Flowcontroller (CFC). Operation mode can be Manual or Auto. In Manual

mode we can manually open MRV1 valve from 0-100% in order to test its

functionality.

In Auto mode we set the Setpoint value of Pressure that we want to

maintain after Flowcontroller. We have Default setpoint which is used if

there is no other CFC Function selected, otherwise other Setpoints are

used.Also for BRV1 valve we have Manual or Auto mode. In Manual mode we

can also manually open BRV1 valve from 0-100% in order to test its

functionality. In Auto mode we adjust the CFC Pressure Diference. If

pressure falls below Setpoint-CFC Press. Diference CFC opens in

order to raise outlet pressure

.

With clicking on icon you are redirected to CFC status page, which is

described in upper pages

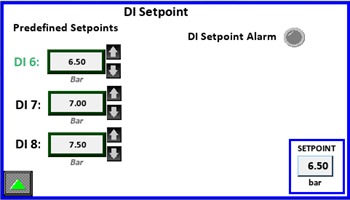

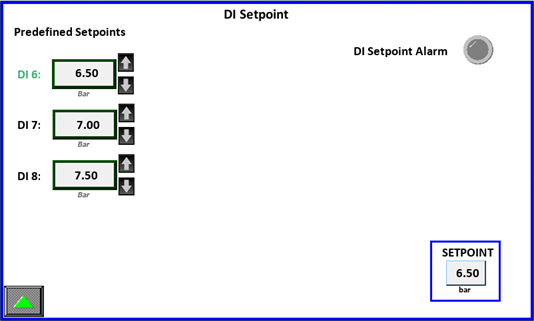

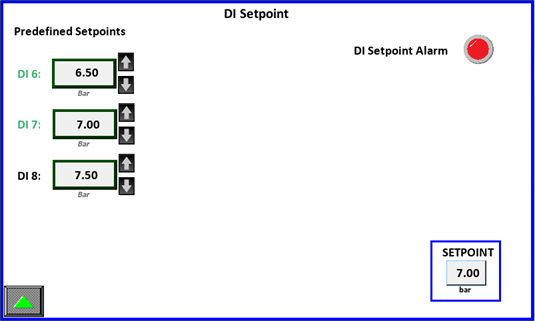

System offers to set the Setpoint for CFC from two different functions.

If none function is selected Default Setpoint is used.

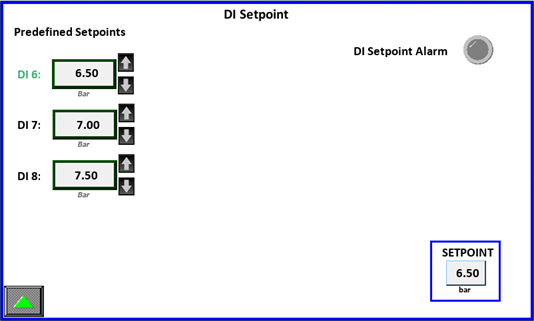

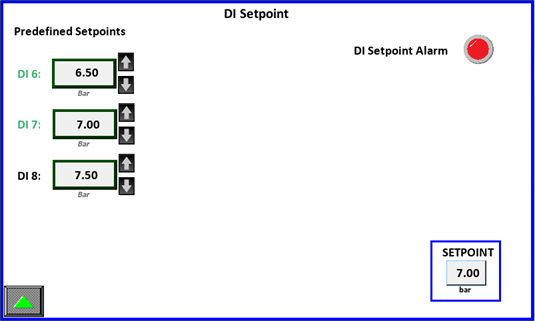

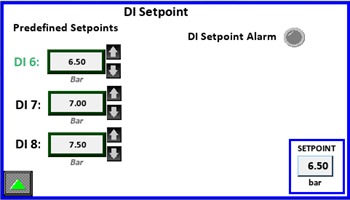

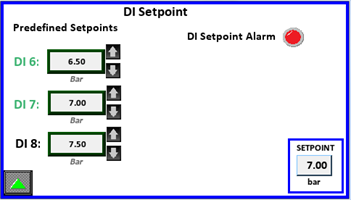

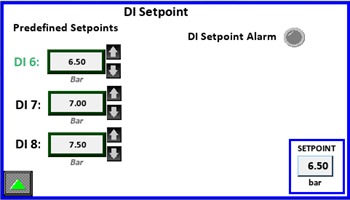

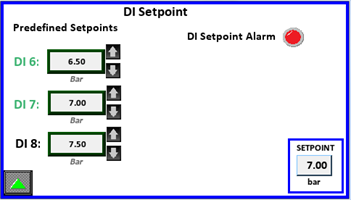

DI Setpoint Function

Here we can set Setpoint via three digital inputs which are predefined

(DI6, DI7, DI8). When certain DI is activated it turns green and at the

bottom on right side you can see which Setpoint is used at the

moment.

Only one DI can be activated at once otherwise DI Setpoint Alarm is

triggered and Default Setpoint is used.

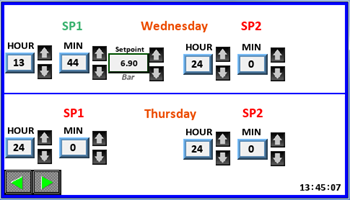

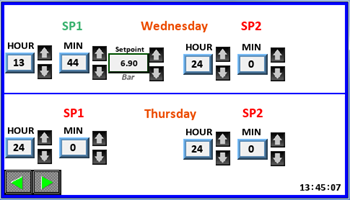

CFC Schedule Function

Here you can adjust schedule for CFC. For each day you can adjust two

different setpointsà SP1 and SP2. When specific Setpoint is used

it turns green. If time adjustments are not OK (if hour setting is 24,

or both SP of the same day have set same time) the setting for Setpoint

disappears and system will not use this SP.

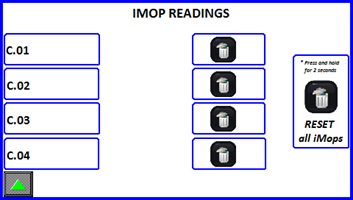

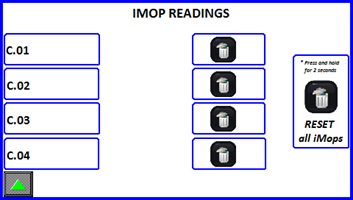

IMOP

Pressing the button enters the IMOP menu. A readings reset button per

compressor is available. IMOP is a function that monitors and writes

values of all AIP variables (all voltages, all currents, all CosFi-s,

reactive power, real power,…) in CSV format and uploads it. If

compressor is ON/OFF type it writes and uploads both states in

difference from VSD compressors for which writes and uploads only one

state à RUNNING. By resetting IMOP readings will be performed and

uploaded again

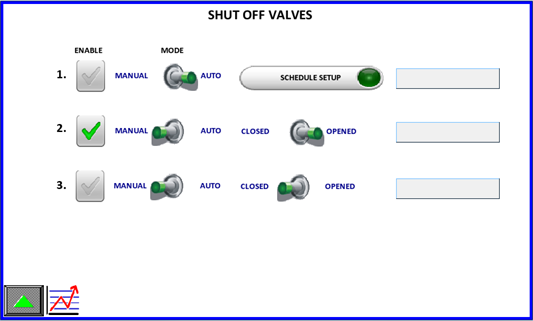

SHUTOFF VALVE SETTINGS

Pressing the button enters the SHUT OFF VALVES menu. If this option is

purchased, operator can set three different shut off valves. They can be

regulated manually ( open-close ) or automatically through schedule

setup. We also can set the name of each valve for easier

recognization.

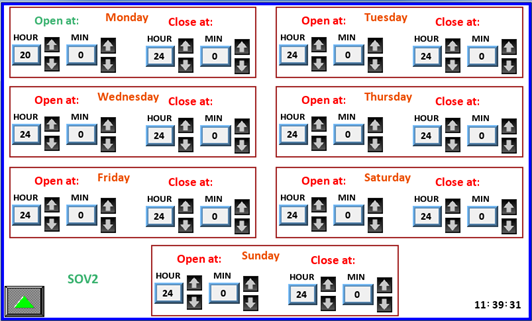

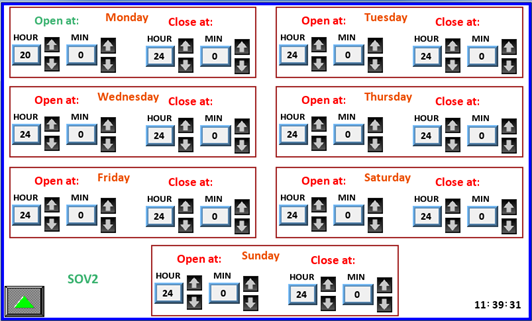

If we want to set the schedule, we click on and then adjust schedule

settings for specific Shut off valve. When is green it means that second

SOV is enabled, otherwise its regulation is disabled.

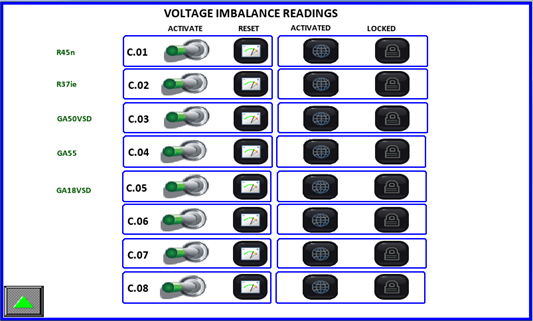

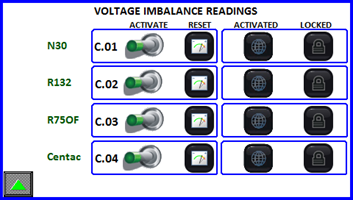

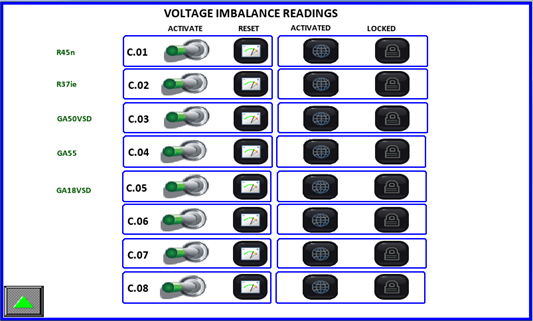

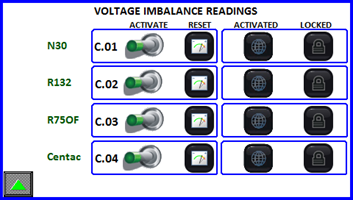

VOLTAGE IMBALANCE

Pressing the button enters the specific menu. Here you can view

function status, activate readings and reset all voltage imbalance

readings. Voltage imbalance is a function that uploads an alarm log file

when supply voltage varies for more than 3% from rated voltage. When

first event happens, a timer of 300 s starts and after the expiry

function waits for next voltage imbalance. After third event of

imbalance the function locks and waits for manual reset on HMI. If the

LOCKED icon is active a reading has already been uploaded. Press and

hold the reset button to reactivate reading and uploading data.

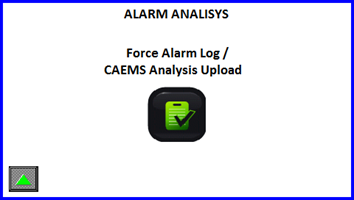

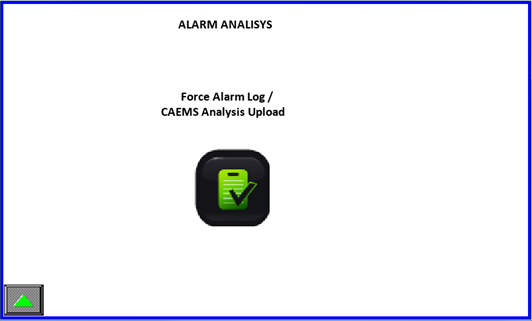

ANALISYS LOG FUNCTION

Pressing the button enters the LOG menu. When you activate this

function, system uploads all values of all variables from 1 minute

before and 1 minute after the function has been activated.

INFO & HELP SCREEN

The remaining buttons on the main selection screen display Info and Help for the CALMS – CAL interface.

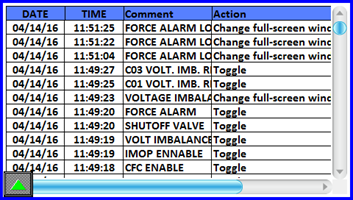

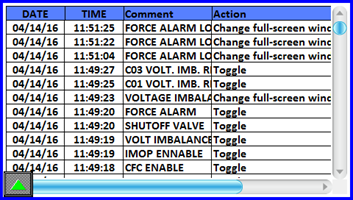

EVENT LOG

From main menu go to event log page by pressing the icon. Event log is

self-explanatory.

ALARM LOG

From main menu go to alarm log page by pressing the icon. Alarm log is

self-explanatory.

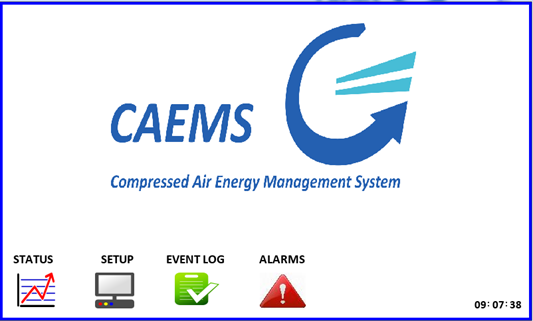

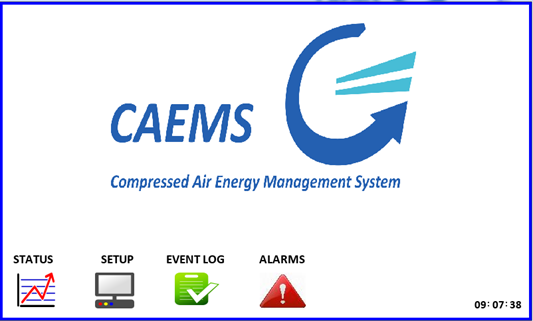

9 HUMAN MACHINE INTERFACE (FOR PM-8)

STATUS SCREENS

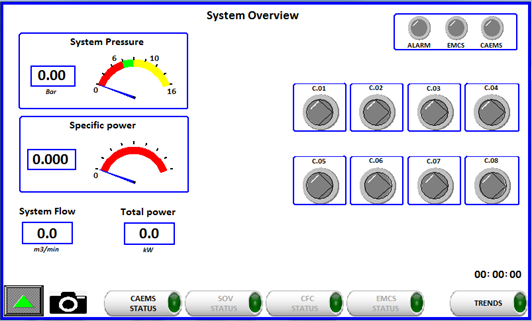

CALMS can be ordered with an optional HMI operator panel. When powering

up the unit the operator panel (OP) will display the HOME screen.

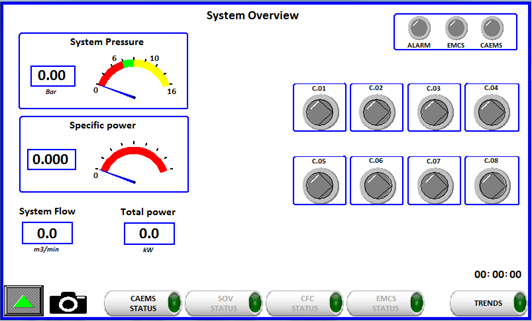

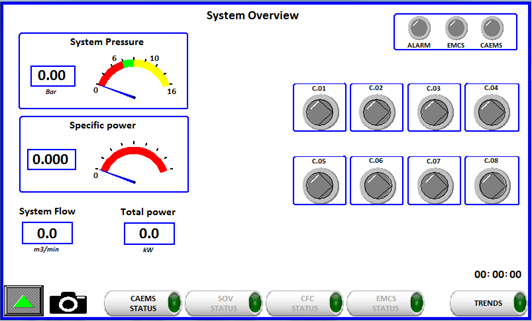

Pressing the icon will send you to the CALMS status menu. Here you have

an overview of your sistem. The squares on the right represent ALARM,

EMCS, CALMS and compressors status.

If any of the states in the upper right corner is active the signal lights will lid up. Below is a picture to represent the status light color. Alarm LED is ON when system alarm is active. That means if pressure is below critical value, if any of compressors is in alarm or one of auxilliary CAL-C modules is disconnected.EMCS light is ON if EMCS Control feature is enabled. CALMS light is ON if CALMS is activated in general settings, pressure is beyond critical and at least one compressor is running.

In the right corner below there are 8 status light to indicate single

compressor state. Compressor states are:

STOPPED RUNNING LOADED ALARM

You can navigate the menu by pressing any of the avaliable buttons. To

return to home page press the button.Pressing the button will activate

the CALMS status menu, wich is composite by several different pages:On

the first status page compressor digital states are

visible.

If any state is active, the lights will turn on in color, otherwise the

displayed color is gray. Upper light represent the same states as in

REVIEW page. On the top you can also see name of the compressor.

You can jump directly to compressor power measurement by pressing the On the PM-8 there are 8 compressor power measurement pages. Here are displayed power related measured values.Notice the CAL-C-0X text . If the text is colored GREEN a CALMS module is connected and recognized, otherwise the text color is RED!

If compressor has enabled MODBUS communication an extra button is

displayed. By pressing this button you enter to compressor MODBUS

parameter pages.

In MODBUS parameter page you can see detailed compressor performance.

How many parameters is shown depends what is the type of the compressor

controller.

The second page of the CALMS STATUS group represents CALMS PM-8 analog and digital input states. Each PM has by default eight digital and eight analog inputs. If a digital state is active the representing light will light up.The analog inputs screen displays measured values. When settings are completely filled, the input tags and measurement values will be displayed in real time.You can also check AI Probe alarm. This light will become red if any of connected sensors is faulty. (it must be set in settings)

Pressing the up button from this screen will show the main selection

screen, otherwise pressing will show the next/previous screen. On next

4 status pages you can see power analyzer values for each

compressor.Next status page is compressors hour status page. Hours are

calculated via running and loaded signals or via MODBUS if enabled. The

hours can be corrected by clicking on fields, but you have to be login

as manager.

Returning to the REVIEW page is done by pressing the up button.

By clicking on you will enter the Shut Off Valves status menu. NOTE:

This feature must be enabled to enter those status menus.Here you can

see statuses of all three SOV. Red or green color of specific valve ( ,

) tells us if specific SOV is enabled or disabled. Red color means that

this SOV is disabled (its regulation is disabled), green color means

that this SOV is enabled (its regulation is enabled).Each SOV is

recognized through “SOV Name” which is given in SOV settings (must be

logged in as Operator). Each SOV can be in AUTO or MANUAL mode. Manual

mode means that valve can be opened or closed via HMI interface by

switching the Open-Close switch. If SOV is in AUTO mode means that valve

is opening, closing via schedule which is set on daily base.Position of

SOV indicates the position of specific

SOV.

Returning to the REVIEW page is done by pressing the up button. By

clicking on you will enter the CFC Status page. NOTE: This feature

must be enabled to be possible to enter those status menus.On CFC Status

page we can see all the vital system and CFC parameters.(Statuses of

compressors, position of CFC valves, Inlet and Outlet pressure, Setpoint

value and System flow. On the top of the window is a status bar which

indicates if which regulation mode CFC is. Here is in MANUAL mode. That

means CFC valves can be regulated manually via HMI interface in CFC

Settings (must be logged in as operator)

.

Returning to the REVIEW page is done by pressing the up button. By

clicking on you will enter the EMCS Status page. NOTE: This feature

must be enabled to be possible to enter those status menus.On first EMCS

status page you can see all the compressors signals, system pressure and

system flow.

You go to next page by clicking icon. On next page you can see

compressors priorities and which compressor is next to start and stop.

Number 9 means that there is none compressor to regulate.

TREND SCREEN

By pressing the button from system overview page it will show the

Analog inputs trends screen. Here you will be able to investigate a

single AI values at desired time.

When any AI0X button is pressed the following screen will be shown:

Pressing the up button from this screen will show the TRENDS selection

screen. Buttons will move to previews/next analog input trendsReturning

to the main selection screen is performed by repetedly pressing the up

button.

ALARM SCREEN

By pressing the button will show the ALARM screen.

Here you will be able see any alarm that has been recorded by the CALMS

system. Alarms must be acknowledged by pressing on the alarm text (text

color with turn to green). Pressing the up button from this screen will

show the main selection screen.

SETUP

Next on the main window is the SETUP icon . Pressing it will show the

SETUP page.

LOGIN SCREEN

Before you can actually enter or enable any setting a operator login is

mandatory. This is done by the following procedure.By pressing the

button in the main manu you will be showed the login screen. Here you

can see which functions are purchased and

enabled.

Password is to be inputed by user. Prior to that any change is

uneditable.

After succcesfull login additional options can be enabled. Enabling the

option will be seen by activity light and text change. Please notice

that not all option are avaliable. Which options will be avaliable is

determined by the option your CALMS is shipped. In the picture below

CFC,EMCS and SHUTOFF VALVE options are purchased therefore are all

avaliable to use.

Pressing the up button from this screen will show the SETUP screen.

After enabling additional options the SETUP page menu looks different:

Pressing the up button from this screen will show the SETUP screen.

After enabling additional options the SETUP page menu looks different:

CALMS SETTINGS SCREEN

By pressing the button will show the SETTINGS screen. There are several

screens where you can input system settings.

Here you MUST input Analog inputs name, min values, max values and measuring units. Current transfomer range must be entered here for each CAL-C module (Compressor). Pressing on an empty box under Analog input name or AI Units opens a keyboard.

COMPRESSOR NAMES AND METER DISPLAY SETTINGS

Compressor names can be given names trought this input page. Here you

can choose, depending on which AI is your system pressure, the correct

AI. Same for system flow. In case system flow is on multiple AI`s you

select “Multiple AI`s” and choose correct analog inputs. Sum of all

AI`s is your system flow from which Specific power is calculated.

If you don’t have connected flowmeter to any of AI’s you can choose

“Calc Flow” and system will calculate the flow. In this case nominal

flow of compressors must be set correctly, otherwise calculation of flow

will not be ok. Here you can also check what is the MAX RANGE of

calculated flow. Default value is 200 m3/min. If necessary it can be

changed, but you have to be logined as Manager. This MAX Range value is

value which is set on CALMS WEB interface as MAX Range of AI21. (AI21 is

reserved for calculated flow)

If you don’t have connected flowmeter to any of AI’s you can choose

“Calc Flow” and system will calculate the flow. In this case nominal

flow of compressors must be set correctly, otherwise calculation of flow

will not be ok. Here you can also check what is the MAX RANGE of

calculated flow. Default value is 200 m3/min. If necessary it can be

changed, but you have to be logined as Manager. This MAX Range value is

value which is set on CALMS WEB interface as MAX Range of AI21. (AI21 is

reserved for calculated flow)

Here you can choose which DI`s you will use as ALARM inputs. If

specific DI as ALARM is used it means that after 60s of active state

alarm output DO4 will be activated and also CALMS Alarm will be

triggered.Depending on what type of digital input you need different

inputs states and logic can be selected here. Here you can set for all

DI’s that are available in your device.

ALARM SETTINGS

Here you can choose which analog inputs are connected to 4-20mA sensors.

System will than constantly checking those inputs. In case of under or

over current of the input alarm will be triggered. NOTE: Default

there are only eight

AI’s.

GENERAL SETTINGS

Here you can acess the HMI setting page and enable or disable the PM-8 functionality. Minimal critical pressure is used to automatically set PM-8 ENABLE/DISABLE button to off if pressure is under that value and all compressors are shutdown. Line voltage setting is used for power calculation ( see below). You can also choose energy specific display or power specific display.

On this page users can select HMI display language by language selector

:

Depending on user location and expected language the selection can be

upgraded. After finishing the setting up of the input return to SETUP

page by pressing the button.

EMCS SETTINGS

If EMCS is purchased and enabled in login page you can acess EMCS

SETTINGS by pressing the EMCS SETTINGS button and a setup screen for

the control system will be displayed. Here you can input EMCS options

such as control pressure, timers and control mode.

the pages with the navigation buttons as usual.

the pages with the navigation buttons as usual.

PRESSURE SETTINGS

On this page user setups EMCS pressure parameters.PRESSURE SETPIONT:

is the desired pressure of the systemCRITICAL PRESSURE: is the

minimum pressure of the system. If pressure goes below that point an

alarm will be issued and additional compressors will be

started.PRESSURE SETPOINT OFFSET: is the below and under Pressure

Setpoint setting. If pressure reaches (Pressure Setpoint + Pressure

Setpoint Offset) next compressor will be unloaded and if pressure

falls below (Pressure Setpoint - Pressure Setpoint Offset) next

compressor will be loaded.MAX. CRITICAL PRESSURE: If pressure

reaches this set value emergency stopping of compressors is

programmed.If pressure settings are setup as above the EMCS will try to

maintain a system pressure between 7,5 and 6,5 bar. If pressure goes

higher compressor will be unloaded, if pressure falls below next

compressor is loaded.

TIMERS

On this page user setups EMCS TIMER settings:NORMAL START: time that

EMCS will wait before starting another compressor in the system if

system pressure falls below (Pressure Setpoint - Pressure Setpoint

Offset).CRITICAL START: time that EMCS will wait before starting

another compressor if system pressure falls below critical pressure set

pointLoad/Unload: time that EMCS will wait before loading or

unloading next compressor.Unload Stop(long): time in which next

unloaded compressor will be stoppedUnload Stop(short): time in which

next unloaded compressor will be stoppedDifference between long/short

timer is in the number of unloaded compressor. If only two or less

compressors are unloaded than long timer is used, otherwise long timer

is used.

IMPORTANT! PRIORITY MUST NOT BE SET AS ZERO. TWO COMPRESSOR CAN’T HAVE

SAME PRIORITY NUMBER!!!Compressor with the HIGHEST starting priority

number will be started FIRST, compressor with LOWEST starting priority

number will be started last.Compressor with the HIGHEST stopping

priority number will be stopped FIRST, compressor with LOWEST stopping

priority number will be stopped last.

IMPORTANT! PRIORITY MUST NOT BE SET AS ZERO. TWO COMPRESSOR CAN’T HAVE

SAME PRIORITY NUMBER!!!Compressor with the HIGHEST starting priority

number will be started FIRST, compressor with LOWEST starting priority

number will be started last.Compressor with the HIGHEST stopping

priority number will be stopped FIRST, compressor with LOWEST stopping

priority number will be stopped last.

CONTROL MODE

Here you select desire control mode. Only one mode can be selected. You

can adjust settings of control mode by clicking on specific icon. You

can click the icon before enabling specific control mode.

PRIORITIES

In this control mode you have two possible options. One option is to

adjust only Primary Starting Priorities and Primary Stopping

Priorities. You can also enable Switching Prio option and system

will then change the compressors priorites every defined days.The LED

shows us which priorities are used at the momentàPrimary or secondary.

ENERGY MODE SETTINGS

Input your flow values and priorities will be acceppted if system flow

is in determined range. Determine the flow average time calculation.

SCHEDULES

You can input three different schedules that must cover whole week. When

next schedule is started previous is aborted. When schedule is active

the correct priorities will be accepted.

Compressor System (CS) Stop-Start FUNCTION

On this page user can stop and start whole compressor system ( CS). By activating this function system will calculate how many compressors are needed to fill the system in prefill time specified by operator. So, when “Auto Start CS” button is pressed, system starts compressors ( how many is calculated from “Pressure tank capacity” and “Prefill time”). When pressing “Auto Stop CS” all compressors will be stopped and system will wait for next command to start CS.

If Start/Stop schedule is enabled, operator has option to adjust

schedule when CS will start and when stop. On picture below we see that

schedule for Monday is disabledàRed LED (If hour for start and stop is

24 then schedule for this day is disabled). For Tuesday we see that

schedule is enabledàGreen LED and time is set. Compressor station will

start at 5.30 and stop at 15.00.Here you can adjust schedule for each

day.

After finishing setup return to the SP page by pressing the UP button.

CFC SETTINGS

From the SETUP PAGE, if the option is purchased and enabled pressing the

button enters the CFC menu.Here is the main setting page for CALMS

Flowcontroller (CFC). Operation mode can be Manual or Auto. In Manual

mode we can manually open MRV1 valve from 0-100% in order to test its

functionality

In Auto mode we set the Setpoint value of Pressure that we want to

maintain after Flowcontroller. We have Default setpoint which is used if

there is no other CFC Function selected, otherwise other Setpoints are

used.Also for BRV1 valve we have Manual or Auto mode. In Manual mode we

can also manually open BRV1 valve from 0-100% in order to test its

functionality. In Auto mode we adjust the CFC Pressure Diference. If

pressure falls below Setpoint-CFC Press. Diference CFC opens in

order to raise outlet pressure.

With clicking on icon you are redirected to CFC status page, which is

described in upper pages.

System offers to set the Setpoint for CFC from two different functions.

If none function is selected Default Setpoint is used.

DI Setpoint Function

Here we can set Setpoint via three digital inputs which are predefined

(DI6, DI7, DI8). When certain DI is activated it turns green and at the

bottom on right side you can see which Setpoint is used at the moment.

Only one DI can be activated at once otherwise DI Setpoint Alarm is

triggered and Default Setpoint is used.

CFC Schedule Function

Here you can adjust schedule for CFC. For each day you can adjust two

different setpointsà SP1 and SP2. When specific Setpoint is used it

turns green. If time adjustments are not OK (if hour setting is 24, or

both SP of the same day have set same time) the setting for Setpoint

disappears and system will not use this SP.

IMOP

Pressing the button enters the IMOP menu. A readings reset button per

compressor is available. IMOP is a function that monitors and writes

values of all AIP variables (all voltages, all currents, all CosFi-s,

reactive power, real power,…) in CSV format and uploads it. If

compressor is ON/OFF type it writes and uploads both states in

difference from VSD compressors for which writes and uploads only one

state à RUNNING. By resetting IMOP readings will be performed and

uploaded again.

SHUTOFF VALVE SETTINGS

Pressing the button enters the SHUT OFF VALVES menu. If this option is

purchased, operator can set three different shut off valves. They can be

regulated manually ( open-close ) or automatically through schedule

setup. We also can set the name of each valve for easier

recognization.

If we want to set the schedule, we click on and then adjust schedule

settings for specific Shut off valve. When is green it means that second

SOV is enabled, otherwise its regulation is disabled.

VOLTAGE IMBALANCE

Pressing the button enters the specific menu. Here you can view

function status, activate readings and reset all voltage imbalance

readings. Voltage imbalance is a function that uploads an alarm log file

when supply voltage varies for more than 3% from rated voltage. When

first event happens, a timer of 300 s starts and after the expiry

function waits for next voltage imbalance. After third event of

imbalance the function locks and waits for manual reset on HMI. If the

LOCKED icon is active a reading has already been uploaded. Press and

hold the reset button to reactivate reading and uploading data.

ANALISYS LOG FUNCTION

Pressing the button enters the LOG menu. When you activate this

function, system uploads all values of all variables from 1 minute

before and 1 minute after the function has been activated.

WARNING: Risk of

Danger

WARNING: Risk of

Danger WARNING: Risk of Electric

Shock

WARNING: Risk of Electric

Shock WARNING: Consult

Manual

WARNING: Consult

Manual

In the right corner below there are 4 status light to indicate single

compressor state. Compressor states are:

In the right corner below there are 4 status light to indicate single

compressor state. Compressor states are:

buttons. To return to home

page press the button.Pressing the button will activate the CAEMS

status menu, which is composite by several different pages:On the first

status page compressor digital states are visible.

buttons. To return to home

page press the button.Pressing the button will activate the CAEMS

status menu, which is composite by several different pages:On the first

status page compressor digital states are visible.

Returning to the REVIEW page

is done by pressing the up button. By clicking on you will enter the

CFC Status page. NOTE: This feature must be enabled to be possible to

enter those status menus.

Returning to the REVIEW page

is done by pressing the up button. By clicking on you will enter the

CFC Status page. NOTE: This feature must be enabled to be possible to

enter those status menus.

Navigate the pages with

the navigation buttons as usual.

Navigate the pages with

the navigation buttons as usual.

Pressing the up button from this screen will show the SETUP screen.

After enabling additional options the SETUP page menu looks different:

Pressing the up button from this screen will show the SETUP screen.

After enabling additional options the SETUP page menu looks different:

If you don’t have connected flowmeter to any of AI’s you can choose

“Calc Flow” and system will calculate the flow. In this case nominal

flow of compressors must be set correctly, otherwise calculation of flow

will not be ok. Here you can also check what is the MAX RANGE of

calculated flow. Default value is 200 m3/min. If necessary it can be

changed, but you have to be logined as Manager. This MAX Range value is

value which is set on CALMS WEB interface as MAX Range of AI21. (AI21 is

reserved for calculated flow)

If you don’t have connected flowmeter to any of AI’s you can choose

“Calc Flow” and system will calculate the flow. In this case nominal

flow of compressors must be set correctly, otherwise calculation of flow

will not be ok. Here you can also check what is the MAX RANGE of

calculated flow. Default value is 200 m3/min. If necessary it can be

changed, but you have to be logined as Manager. This MAX Range value is

value which is set on CALMS WEB interface as MAX Range of AI21. (AI21 is

reserved for calculated flow)

the pages with the navigation buttons as usual.

the pages with the navigation buttons as usual. IMPORTANT! PRIORITY MUST NOT BE SET AS ZERO. TWO COMPRESSOR CAN’T HAVE

SAME PRIORITY NUMBER!!!Compressor with the HIGHEST starting priority

number will be started FIRST, compressor with LOWEST starting priority

number will be started last.Compressor with the HIGHEST stopping

priority number will be stopped FIRST, compressor with LOWEST stopping

priority number will be stopped last.

IMPORTANT! PRIORITY MUST NOT BE SET AS ZERO. TWO COMPRESSOR CAN’T HAVE

SAME PRIORITY NUMBER!!!Compressor with the HIGHEST starting priority

number will be started FIRST, compressor with LOWEST starting priority

number will be started last.Compressor with the HIGHEST stopping

priority number will be stopped FIRST, compressor with LOWEST stopping

priority number will be stopped last.