Instructions for the use of CALMS Compressed Air Leak Management system

We have developed a internet based application CALMS for dealing with compressed air leakages, based on experience in eliminating leaks and learning on many mistakes. It is very important to eliminate leaks and include company management in the program, so we have developed Internet-based software that allows rapid creation of reports by cost and quantitative evaluation of the work. CALMS encourages companies to carry out inspections and eliminate leaks. CALMS is a tool for the maintenance team, which systematically eliminates and records leaks in the company as well as for the management company that has control over a very important costly energy product - compressed air. At the same time CALMS tool is used by an external company, which makes once in a period (usually 1 year) review and approval of the leak management. An additional advantage is that CALMS enables easy and fast data input, transparency and automatically generate reports for management and maintenance.

In industry, there are only a few processes that work well without the organization and documentation, as is the elimination of leakage. To effectively eliminate leakages it is necessary to introduce and implement systematic system for leak management, well documented and continuously eliminates leaks. The program should have a complete reporting system that meets the operational part of the records of all leaks, total cost, inventory of spare parts and an accurate assessment of the necessary repairs to the Director’s report with cost and quantitative analysis. To eliminate leaks we need to know exactly where and why these leaks occur and how we can make improvements that this will no longer occur. If the company does not have a system program with all the necessary documentation, system analysis and the possibility of finding solutions to very quickly return to the initial level of leakage.

Leakage is costing the company a lot every hour when compressors are in operation. Of course the obvious, but in practice we forget that saving occurs only when you eliminate the leaks, it is necessary to immediately review and repair the leaks.

Basic steps in eliminating leakages:

First Specify the size of leaks in the application and create a new review CALMS

Mark the leaks and enter them in the application

Repair leak (starting with the largest)

Evaluate work and periodically repeat steps 1. to 4.

1.There are several ways to determine the size of the leak:

- For small systems (less than 50 kW) is suitable leak test (pressure drop test):

Some text

Leakage = Vk * (T / (T + t))

where T = CA Network Charge Time t = CA Network discharge time Vk = compressor capacity.

Measurements should be repeated at least 3 times. Accuracy is of the order of 15%.

- For larger systems (over 50 kW) is a suitable method of flow measurement, when there is no production in the plant. But remember that there are also leakages present only in production time.

- For the detection of leaks can use your sense of hearing, which is in an industrial environment very limited, so it is only suitable for the detection of major leaks or performance preiiskave halted production at the time. For serious work needed ultrasonic leak detector that allows detection of even the smallest leaks during production when operating any machinery. Ultrasonic detectors hear the sound of high frequencies above 20kHz, the typical use at 40 kHz. High frequency sound caused by turbulent flow, which is due to the transition from the higher pressure fluid to lower and is very focused, which simplifies the search.

Ultrasonic detector and leak detection procedure

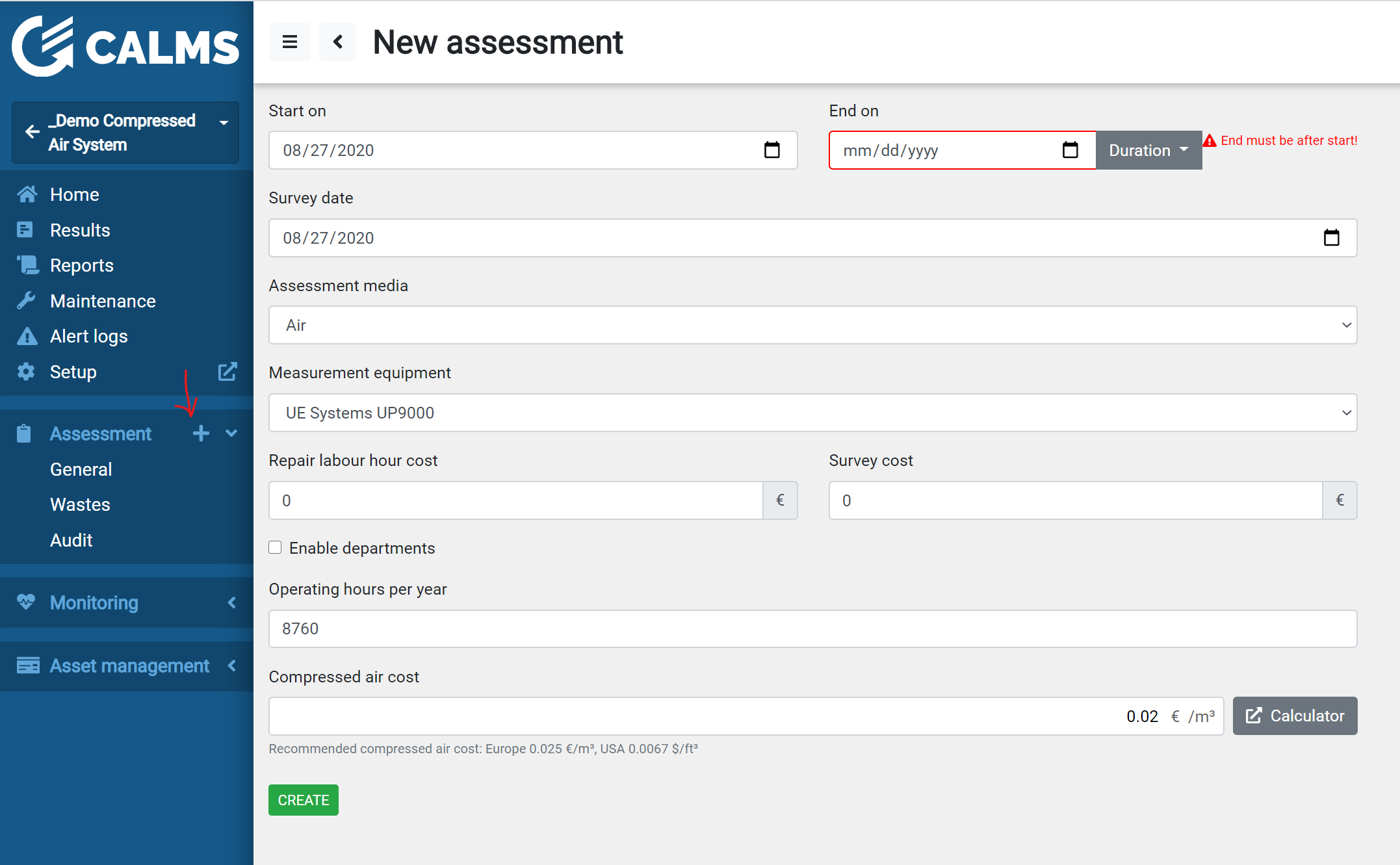

Before you start detecting leaks you should create new System and Assessment in CALMS web internet application.

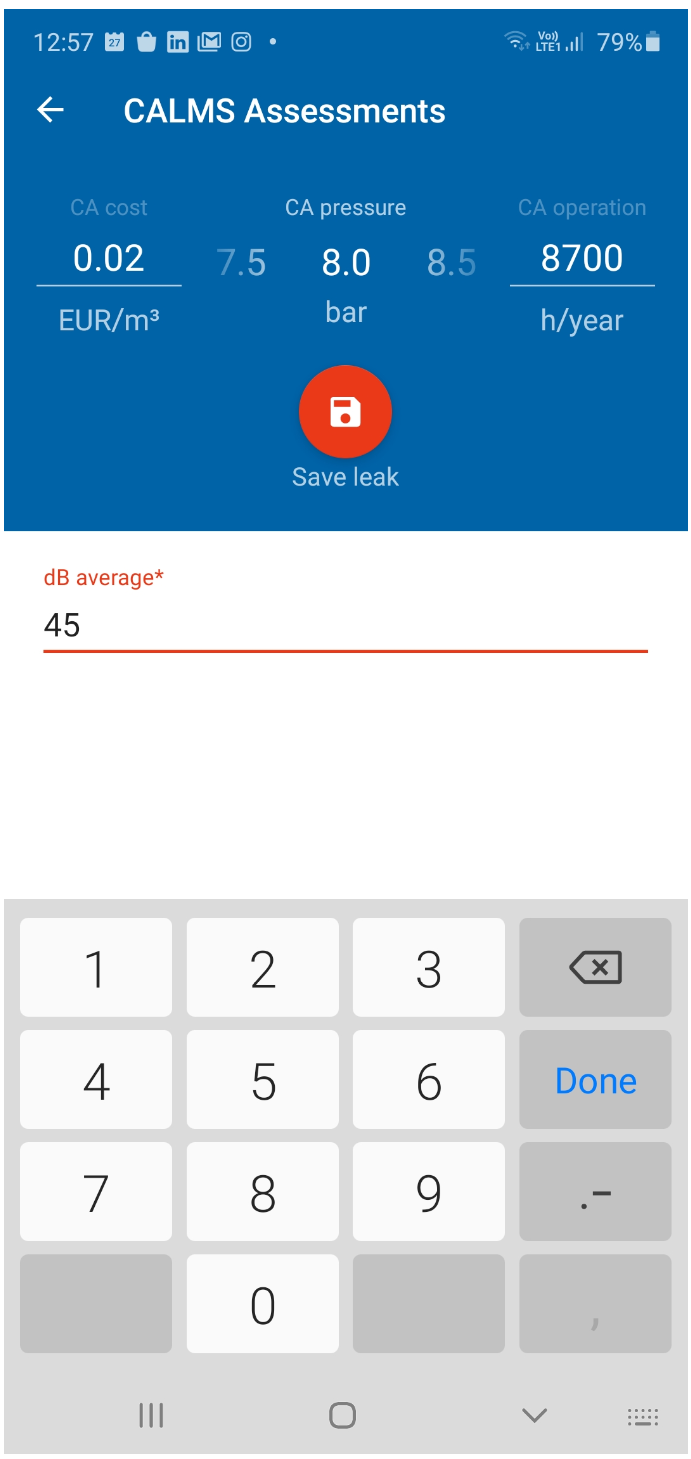

With ultrasonic leak detector you should work from gross to fine. First from a distance up to 10 m locate the leakage spot, then go closer to 30-50 cm. Use rubber focus mount on the detector. On the display of detector read the leak value in dB and enter in the application. Tag the leak with a specific serial identification number. Take leakage picture with your camera or mobile phone from far and near to see the tag with a number. In the CALMS table (internet application on PC or mobile phone) enter the micro-location, description of the leak and the estimated material & repair time.

- The essence of a systematic program CALMS (find and elimination of leaks) is in the documentation and labeling sites with relevant tags and photos of the leaks. Digital ultrasonic detector allows us to use values in dB in a recording system, where the given data automatically estimate the amount of leak. You should enter every leak in the internet application CALMS with leak photo.

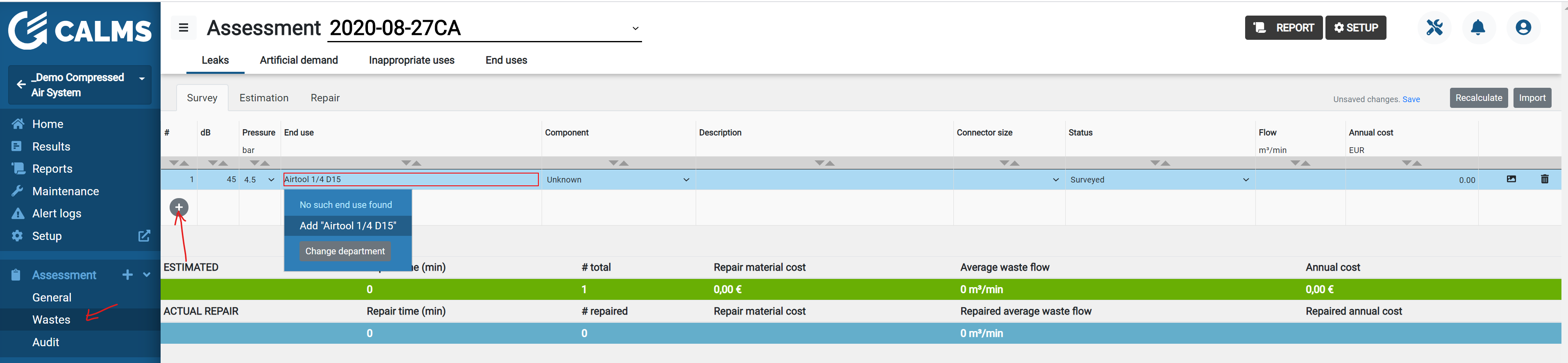

Web leak interface

Mobile app Leak interface

Leakage is estimated based on system pressure, level of noise dB and is evaluated based on the stylistically tested table of flow measurements vs. dB. Estimated leakage flow is only an indication, based on the average measurements of various leaks. Leaks are in no way exact measured values but only estimation..

In eliminating leaks start with the biggest and continue with smaller one, until you fix all the leaks. To eliminate some of the leaks you need to be in time with plant production. Type and number of leakages define the scope of the work. Assembly line with a hundreds or more air tools will have significantly more leakages than process line with more pipelines and fewer connections. Some leaks are associated with the purchase department. On the market there are some models of connecting tubes, connectors and quick couplers, which are significantly less prone to leaks. The purchase price of these items is usually slightly higher, but acceptable given the high cost of leak and the necessary subsequent repair. Also in the internet application CALMS you should enter each repair, along with the time spent and repair material.

- For the evaluation of the work the more you practice the better you are. If you get below 10% leakage, you are very good. Satisfactory results were also recorded where the pressure drop from the compressor station to the farthest point of use is less than 5% of the rated pressure. The aim should be not more than 5% leakage. Leaks should be eliminated to the extent that the need for air could be covered with less compressors – we should be able to shut down one or more compressors. Less ambitious goals are just a waste of time.